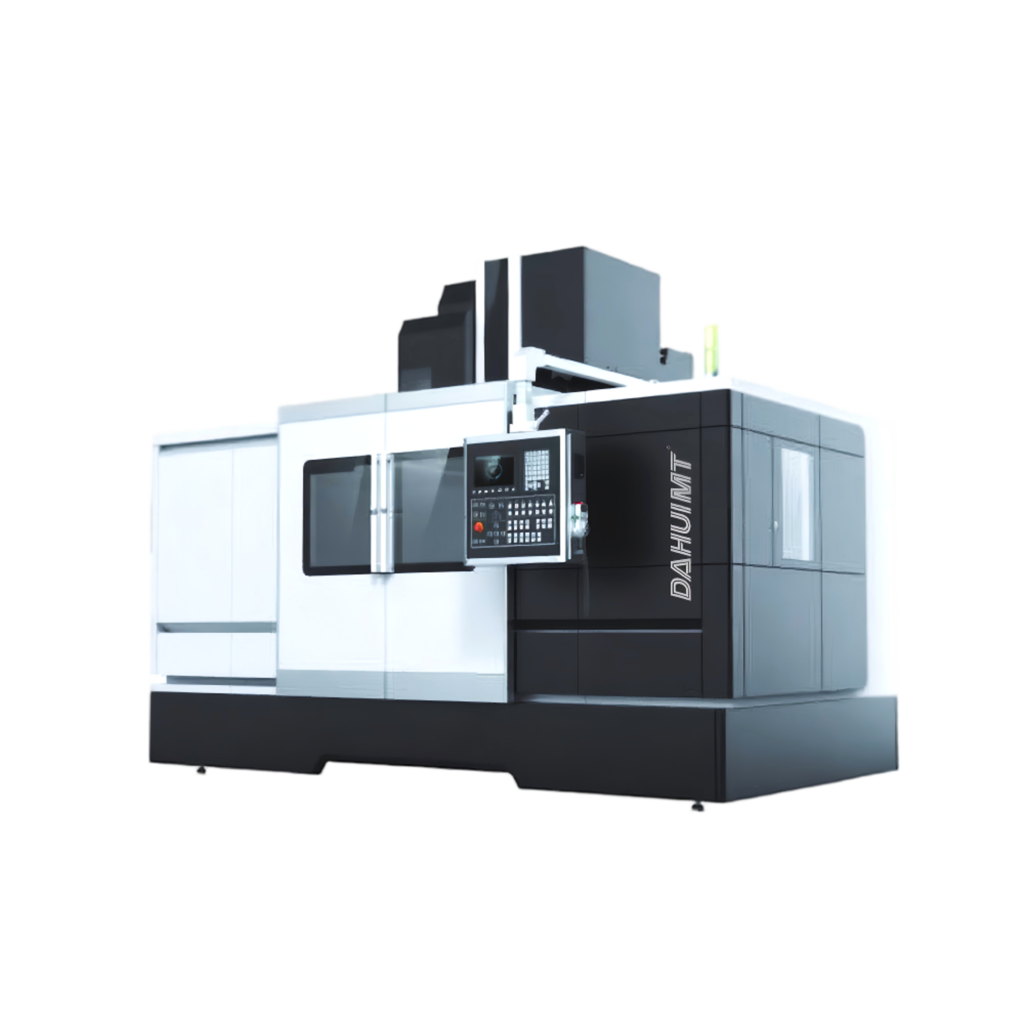

The DVV Series Vertical Machining Center is one of the vertical machining centers independently developed and manufactured by our company. It is ideal for processing complex mold contours, auto parts, and box-type components for the service industry, demonstrating outstanding performance especially in mold machining.

Spindle speed:6000/8000/12000/15000rpm

System:Siemens/Fanuc/Mitsubishi/GSK/HNC

Tool position:24/30/40/60

Expansion:4th axis/cradle rotary table/measuring device/tool management/spindle internal cool-ing/hard rail

Customized models available

We would be happy to make an individual offer for you!

X/Y/Z Axis Travel (mm)

1020/550/510

X/Y/Z Axis Rapid Traverse (m/min)

30/30/20

Positioning/Repeatability Accuracy (mm)

0.008/0.005

Load Capacity (Kg)

800

Overall Dimensions (mm)

3398×2880×2847

X/Y/Z Axis Travel (mm)

1530/740/660

X/Y/Z Axis Rapid Traverse (m/min)

30/30/20

Positioning/Repeatability Accuracy (mm)

0.008/0.007

Load Capacity (Kg)

1500

Overall Dimensions (mm)

4022×4008×3437

X/Y/Z Axis Travel (mm)

2060/950/850

X/Y/Z Axis Rapid Traverse (m/min)

20/20/15

Positioning/Repeatability Accuracy (mm)

0.012/0.007

Load Capacity (Kg)

2500

Overall Dimensions (mm)

5458×5380×3601

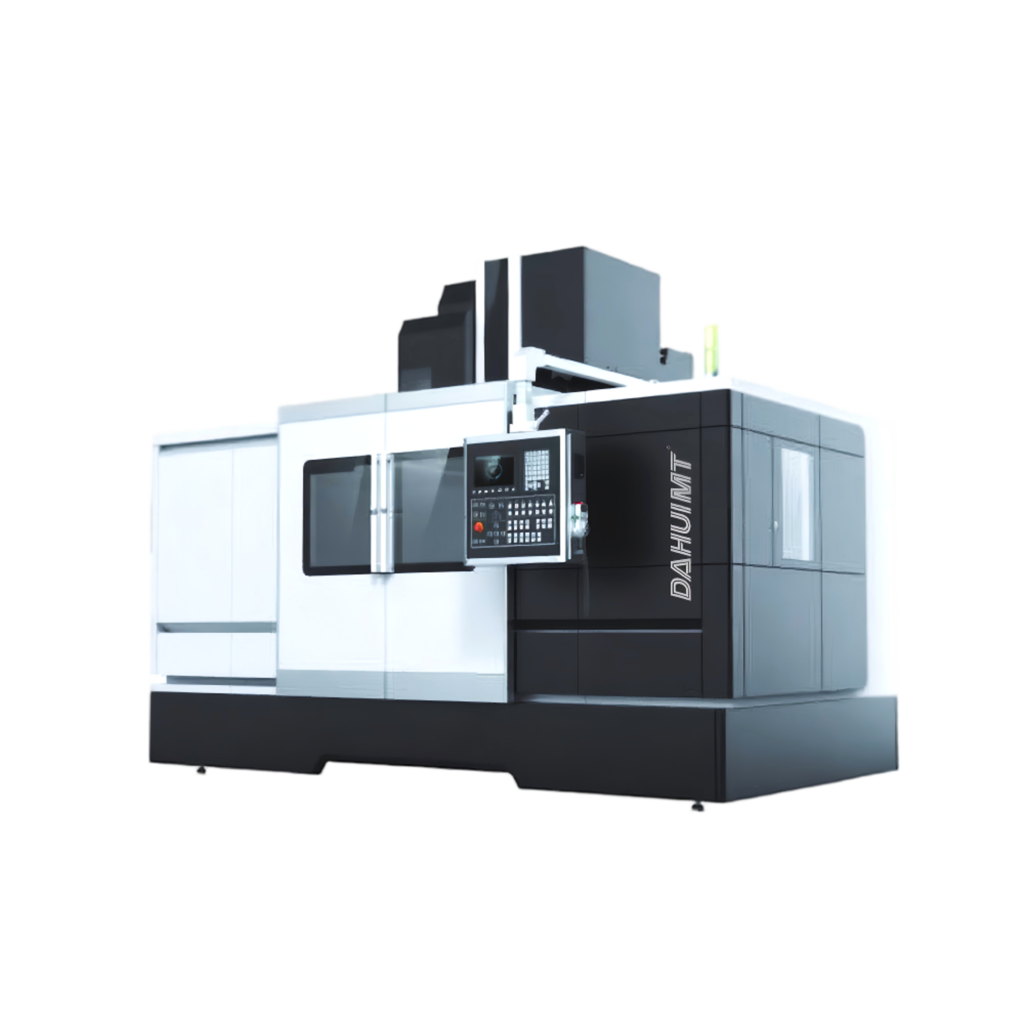

The DVF Series vertical machining centers are designed with hardened guideways and optimized structures for superior rigidity in mold processing and precision part milling. Featuring high-speed spindles, automatic tool changers, and FANUC/Siemens systems, these vertical machining centers (VMCs) handle plate, disc, and shell components with outstanding accuracy. Ideal for mold making, automotive tooling, and general CNC milling, the VDF Series delivers reliable performance in vertical CNC machining environments.

Spindle speed:6000/8000/12000/15000rpm

System:Siemens/Fanuc/Mitsubishi/GSK/HNC

Tool position:24/30/40/60

Expansion:4th axis/cradle rotary table/measuring device/tool management/spindle internal cool-ing/hard rail

Customized models available

X/Y/Z Axis Travel (mm)

860/510/560

X/Y/Z Axis Rapid Traverse (m/min)

24/24/20

Positioning/Repeatability Accuracy (mm)

0.008/0.005

Load Capacity (Kg)

500

Overall Dimensions (mm)

2496×2530×2679

X/Y/Z Axis Travel (mm)

1560/830/790

X/Y/Z Axis Rapid Traverse (m/min)

15/15/12

Positioning/Repeatability Accuracy (mm)

0.008/0.005

Load Capacity (Kg)

2500

Overall Dimensions (mm)

4580×3250×3120

X/Y/Z Axis Travel (mm)

1880/830/790

X/Y/Z Axis Rapid Traverse (m/min)

15/15/12

Positioning/Repeatability Accuracy (mm)

0.008/0.005

Load Capacity (Kg)

2500

Overall Dimensions (mm)

5200×3250×3120

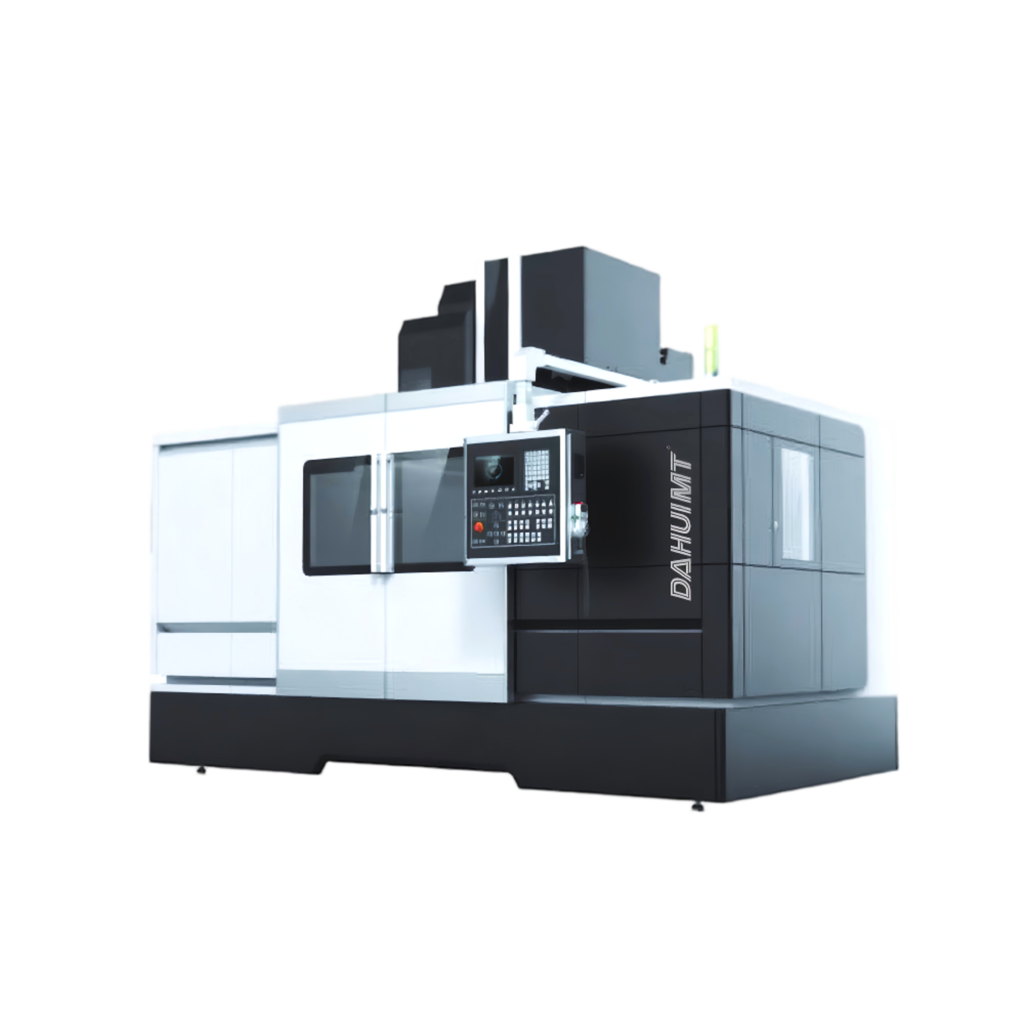

The DVS Series high-speed vertical machining centers utilize linear roller guides for rapid traverses and precision milling, drilling, and tapping. Equipped with FANUC or Siemens CNC controls and robust cast bases, these VMCs excel in aerospace, medical device, and general precision machining. Optimize your workflow with fast, accurate vertical machining centers engineered for high-volume CNC production and superior surface quality.

Spindle speed:6000/8000/12000/15000rpm

System:Siemens/Fanuc/Mitsubishi/GSK/HNC

Tool position:24/30/40/60

Expansion:4th axis/cradle rotary table/measuring device/tool management/spindle internal cool-ing/hard rail

Customized models available

X/Y/Z Axis Travel (mm)

860/510/560

X/Y/Z Axis Rapid Traverse (m/min)

36/36/30

Positioning/Repeatability Accuracy (mm)

0.008/0.005

Load Capacity (Kg)

600

Overall Dimensions (mm)

2496×2530×2679

X/Y/Z Axis Travel (mm)

1040/580/620

X/Y/Z Axis Rapid Traverse (m/min)

36/36/30

Positioning/Repeatability Accuracy (mm)

0.008/0.005

Load Capacity (Kg)

750

Overall Dimensions (mm)

2800×2671×2820

X/Y/Z Axis Travel (mm)

1220/620/685

X/Y/Z Axis Rapid Traverse (m/min)

36/36/30

Positioning/Repeatability Accuracy (mm)

0.008/0.005

Load Capacity (Kg)

1200

Overall Dimensions (mm)

2990×2641×2759

X/Y/Z Axis Travel (mm)

1290/580/620

X/Y/Z Axis Rapid Traverse (m/min)

36/36/30

Positioning/Repeatability Accuracy (mm)

0.008/0.005

Load Capacity (Kg)

750

Overall Dimensions (mm)

3100×2671×2820

We would be happy to make an individual offer for you!

The DVV/DVF/DVS series all adopt topology optimization for bed design, balancing structural rigidity and weight across their product lines.

All three series are equipped with high-performance motorized spindles, tailored to match their respective precision machining requirements.

The DVV/DVF/DVS series feature tailored high-response drive solutions, adapting to varied efficiency needs for different machining scenarios.

Relying on rigid structures and precision guideways, all three series maintain consistent machining stability and accuracy in long-term operation.

Each series is fitted with an efficient cooling system, supporting continuous machining by preventing equipment thermal deformation.

The DVV/DVF/DVS series use mainstream CNC systems (FANUC/Siemens), ensuring user-friendly operation and strong compatibility.

Collectively, the three series cover a wide range of axis travels, meeting precision machining needs for small-to-medium workpieces of various sizes.

All series are configured with suitable tool magazine setups (disk/arm-type), enabling seamless multi-process continuous machining.

Each series is equipped with a high-efficiency chip conveyor, promptly handling machining chips to keep production processes smooth.

The DVV/DVF/DVS series’ cutting fluid systems deliver precise supply, aiding cooling, chip removal, and tool life extension.