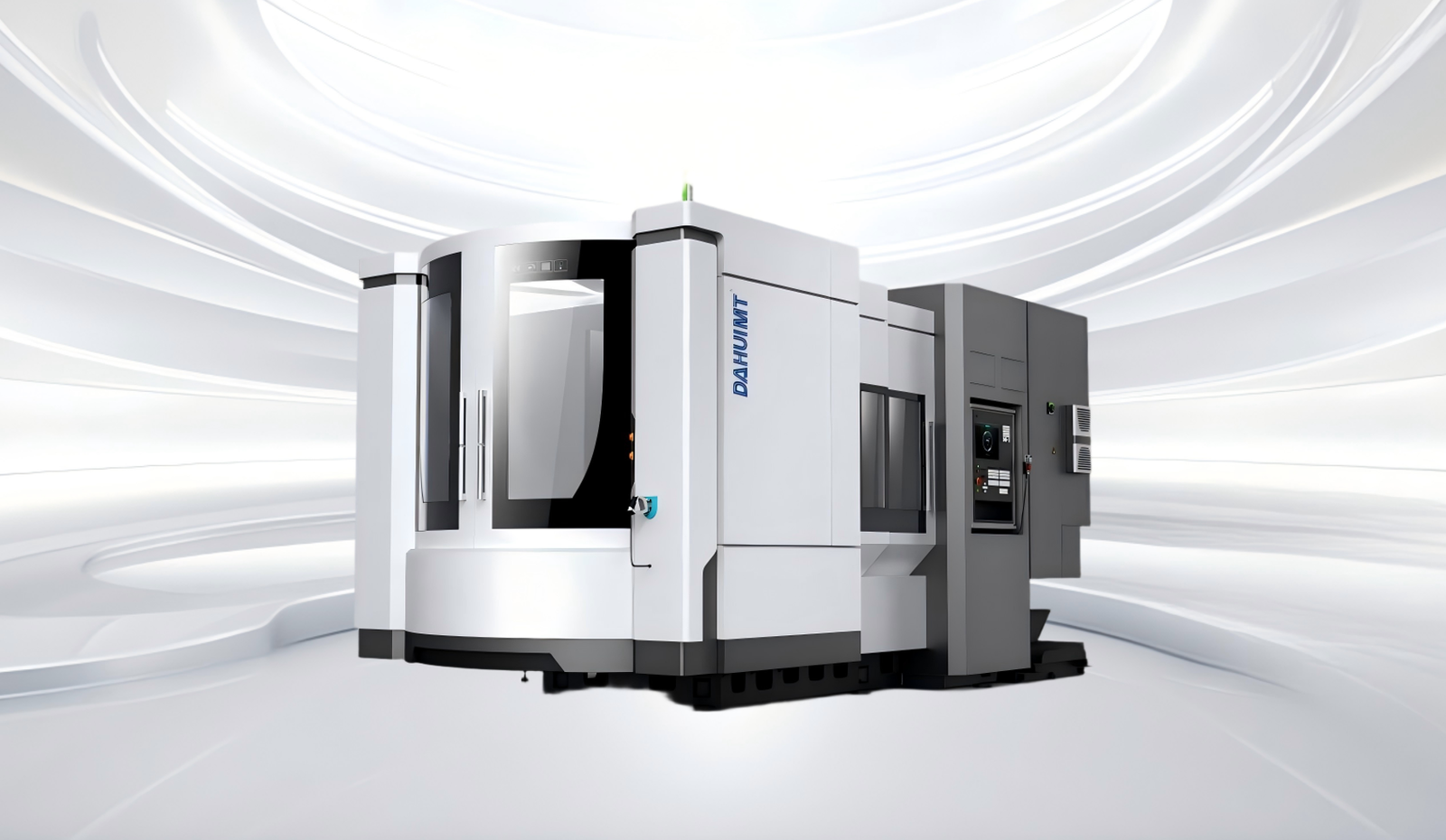

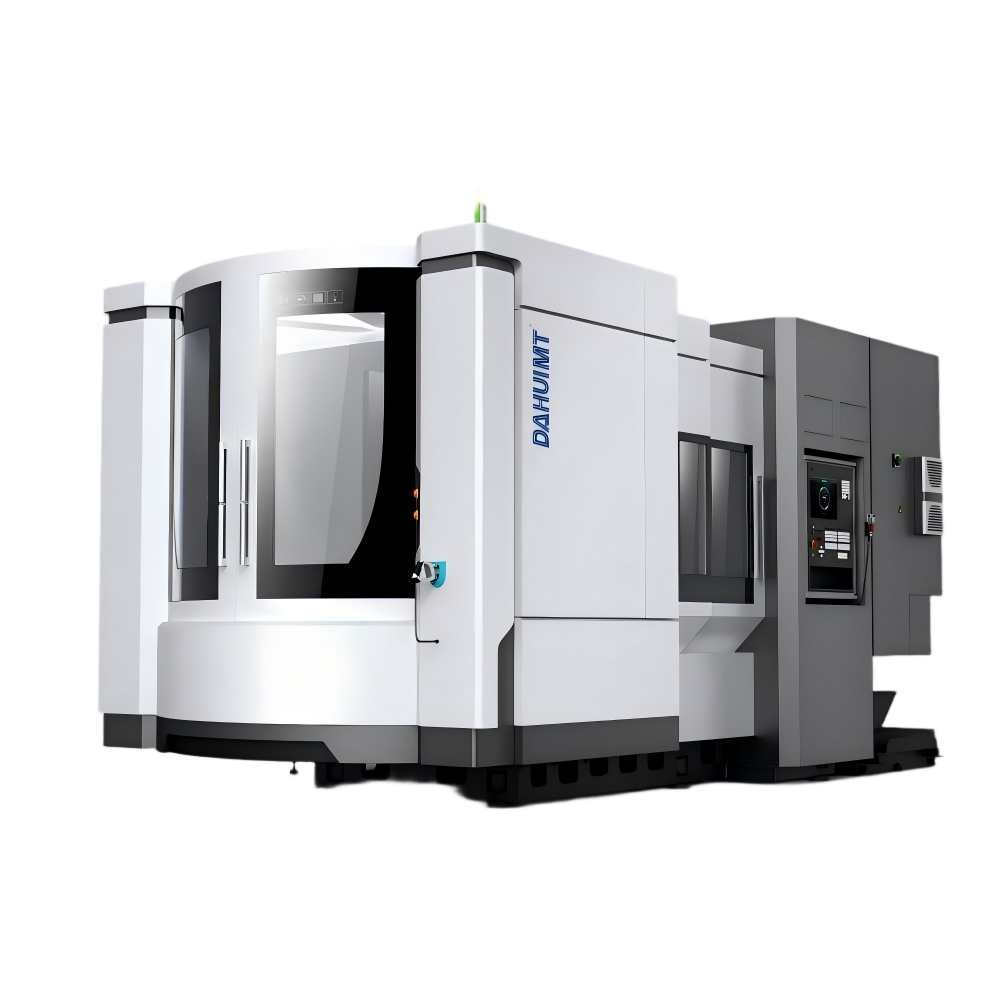

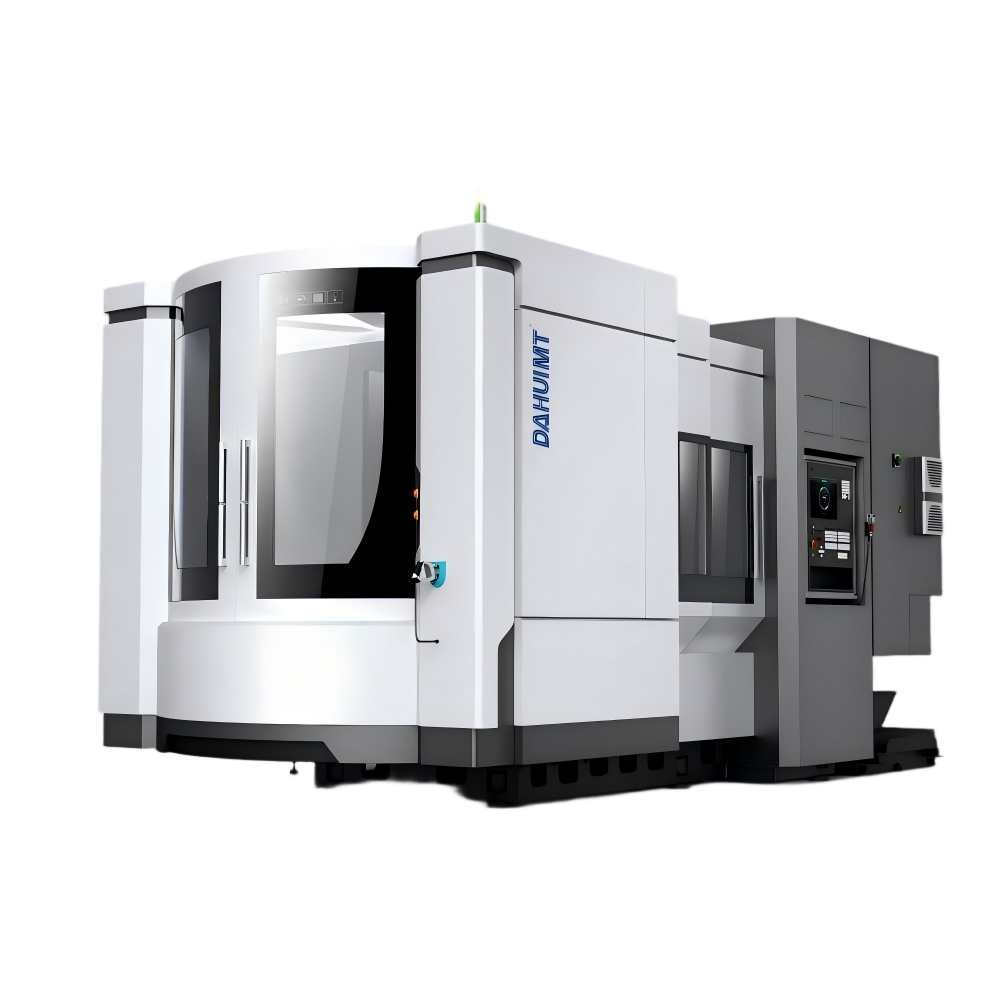

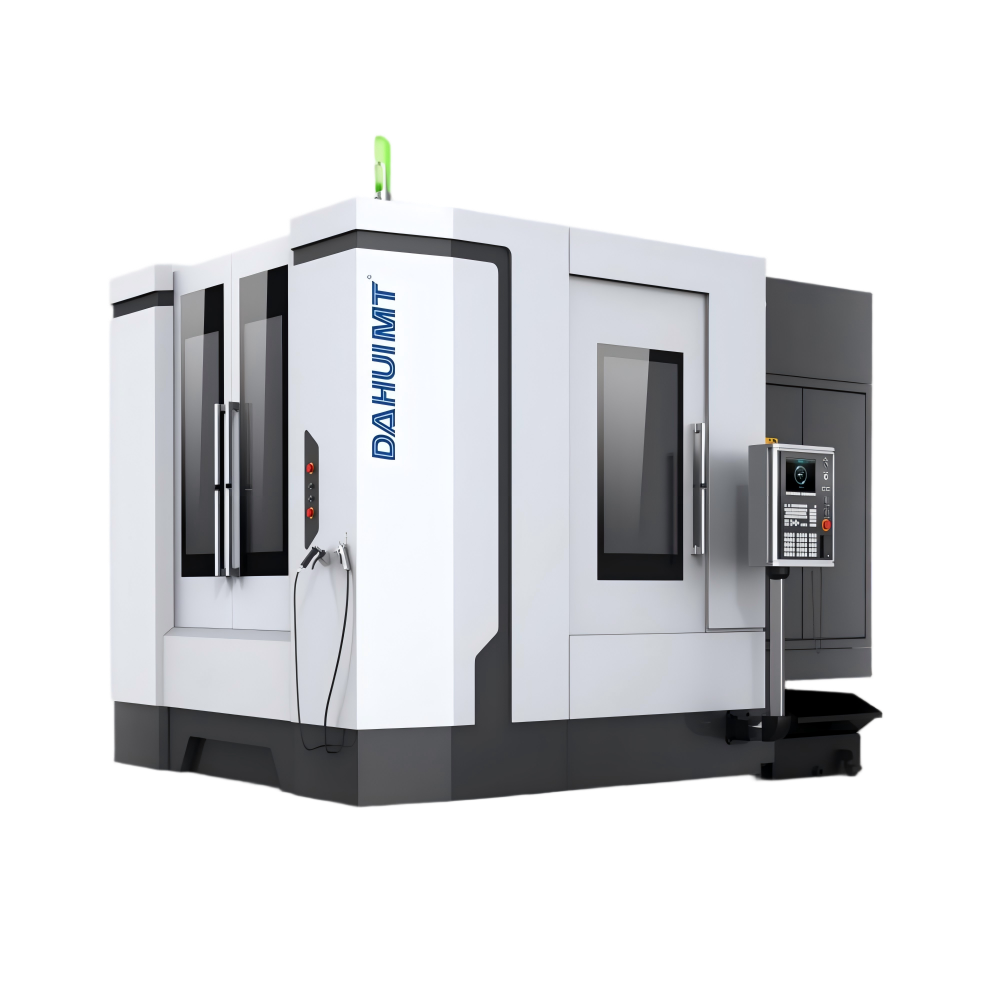

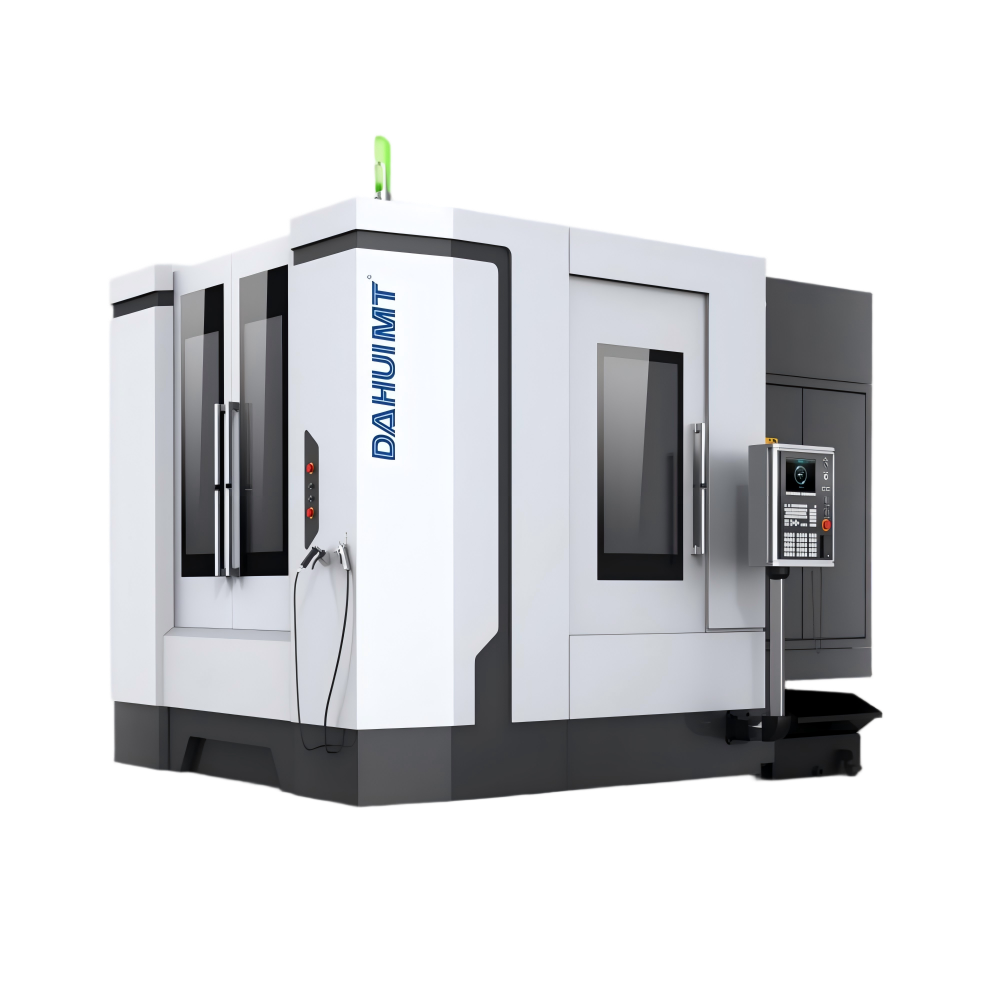

The DHM Series horizontal machining centers feature robust cast structures and hollow-cooled spindles—delivering thermal stability and high rigidity for heavy cutting, supporting multi-face precision machining of large boxes, shells and complex parts.

Table indexing: IT rotary table 1o *360/BRT rotary table 0.001*360

Spindle speed:4000/6000/8000/12000/15000 rpm

System: Siemens / Fanuc

Tool position:40/60/80/120

Expansion:4-axis linkage/measuring device/tool management/spindle internal cooling/normal pres-sure table/full closed-loop encoder

Customized models available

We would be happy to make an individual offer for you!

X/Y/Z Axis Travel (mm)

630/620/710

X/Y/Z Axis Rapid Traverse (m/min)

60/60/60

Positioning/Repeatability Accuracy (mm)

0.008/0.005

Load Capacity (Kg)

400

Overall Dimensions (mm)

5952×2524×2771

X/Y/Z Axis Travel (mm)

780/750/800

X/Y/Z Axis Rapid Traverse (m/min)

54/54/54

Positioning/Repeatability Accuracy (mm)

0.008/0.005

Load Capacity (Kg)

800

Overall Dimensions (mm)

4912×3200×3125

X/Y/Z Axis Travel (mm)

1050/900/900

X/Y/Z Axis Rapid Traverse (m/min)

54/54/54

Positioning/Repeatability Accuracy (mm)

0.010/0.006

Load Capacity (Kg)

1300

Overall Dimensions (mm)

5145×3342×3355

X/Y/Z Axis Travel (mm)

1400/1100/1050

X/Y/Z Axis Rapid Traverse (m/min)

45/45/45

Positioning/Repeatability Accuracy (mm)

0.010/0.006

Load Capacity (Kg)

2000

Overall Dimensions (mm)

6422×3682×3827

X/Y/Z Axis Travel (mm)

1700/1400/1240

X/Y/Z Axis Rapid Traverse (m/min)

45/45/45

Positioning/Repeatability Accuracy (mm)

0.012/0.007

Load Capacity (Kg

3000

Overall Dimensions (mm)

8180×5120×3702

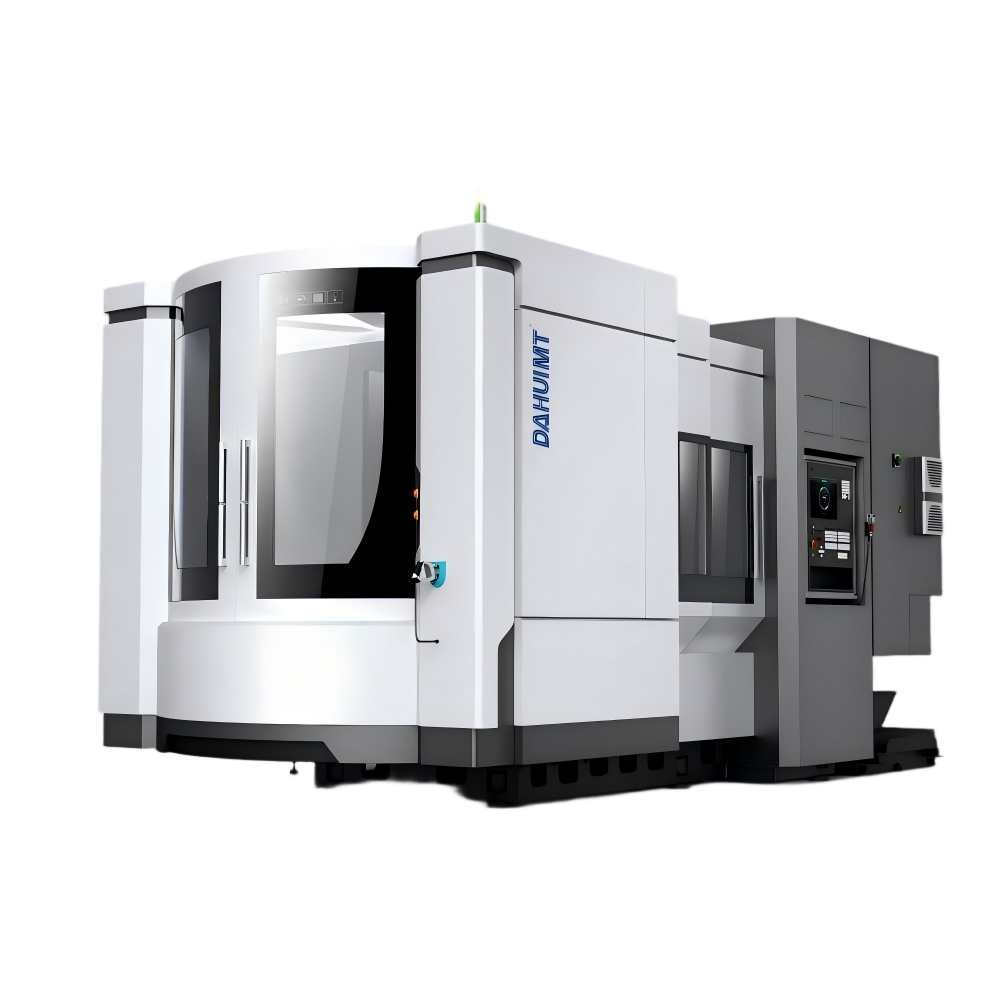

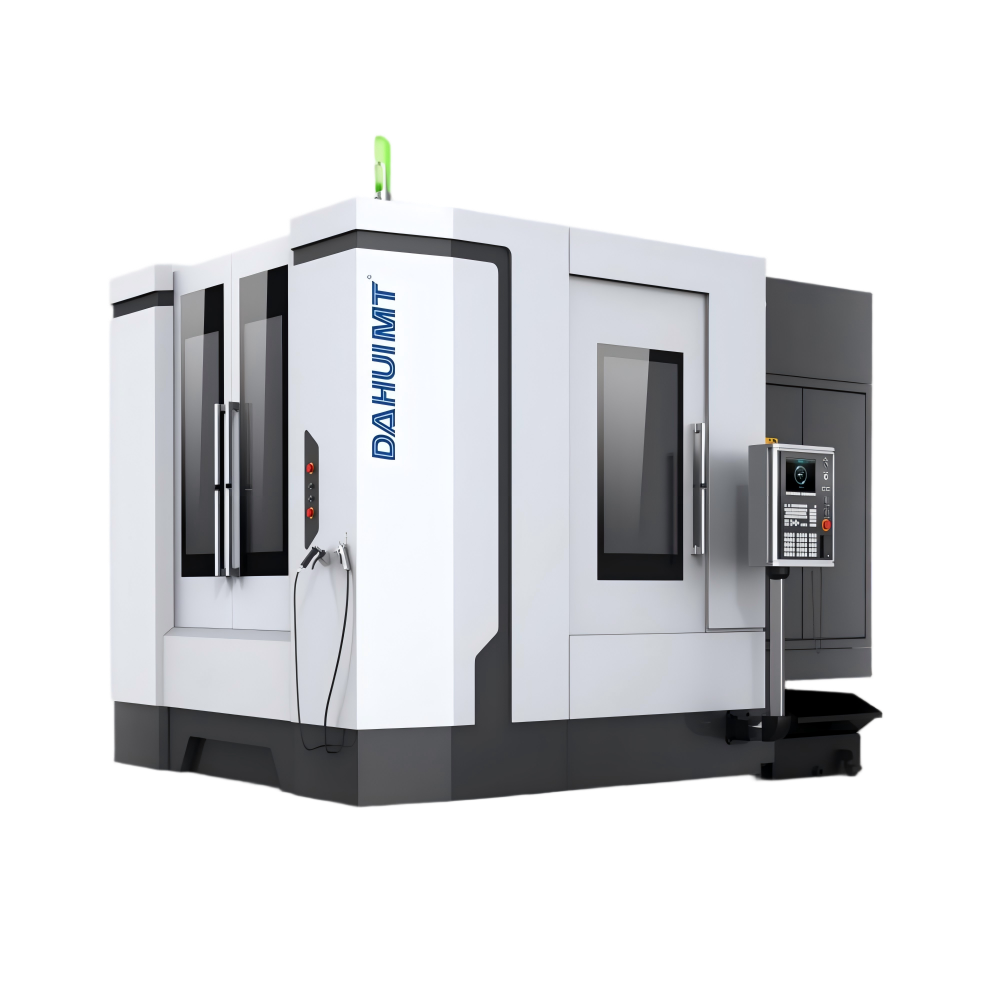

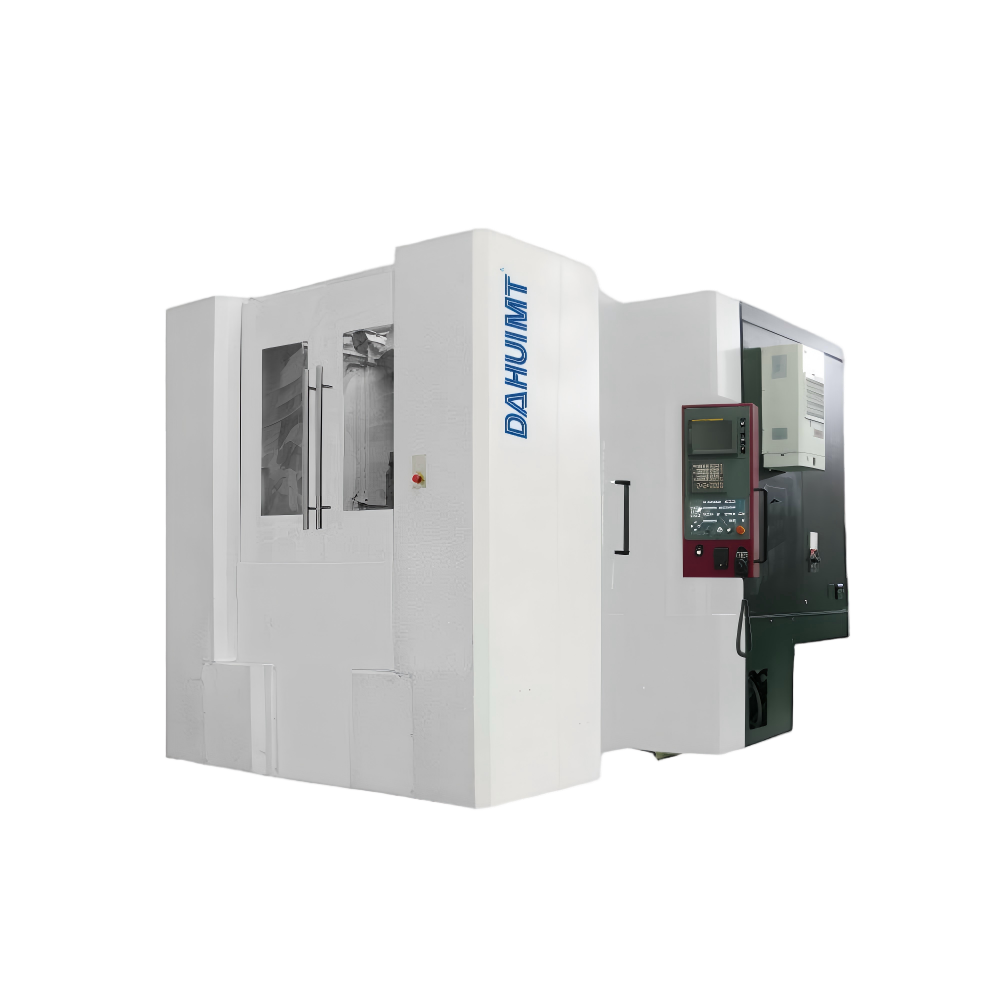

The DHA Series horizontal machining centers boast high-rigidity layouts, high-speed spindles and automatic tool changers—supporting four-face milling, boring, drilling and tapping for boxes, shells and precision parts.

Table indexing: IT rotary table 1o *360/BRT rotary table 0.001*360

Spindle speed:4000/6000/8000/12000/15000 rpm

System: Siemens / Fanuc

Tool position:40/60/80/120

Expansion:4-axis linkage/measuring device/tool management/spindle internal cooling/normal pres-sure table/full closed-loop encoder

Customized models available

X/Y/Z Axis Travel (mm)

780/750/800

X/Y/Z Axis Rapid Traverse (m/min)

54/54/54

Positioning/Repeatability Accuracy (mm)

0.008/0.005

Load Capacity (Kg)

800

Overall Dimensions (mm)

4153×3200×3125

X/Y/Z Axis Travel (mm)

1050/900/900

X/Y/Z Axis Rapid Traverse (m/min)

54/54/54

Positioning/Repeatability Accuracy (mm)

0.010/0.006

Load Capacity (Kg)

1300

Overall Dimensions (mm)

4450×3342×3350

X/Y/Z Axis Travel (mm)

1400/1100/1050

X/Y/Z Axis Rapid Traverse (m/min)

45/45/45

Positioning/Repeatability Accuracy (mm)

0.010/0.006

Load Capacity (Kg)

2000

Overall Dimensions (mm)

5533×3682×3827

X/Y/Z Axis Travel (mm)

2100/1500/1500

X/Y/Z Axis Rapid Traverse (m/min)

45/45/45

Positioning/Repeatability Accuracy (mm)

0.012/0.007

Load Capacity (Kg)

5000

Overall Dimensions (mm)

6595×5520×3827

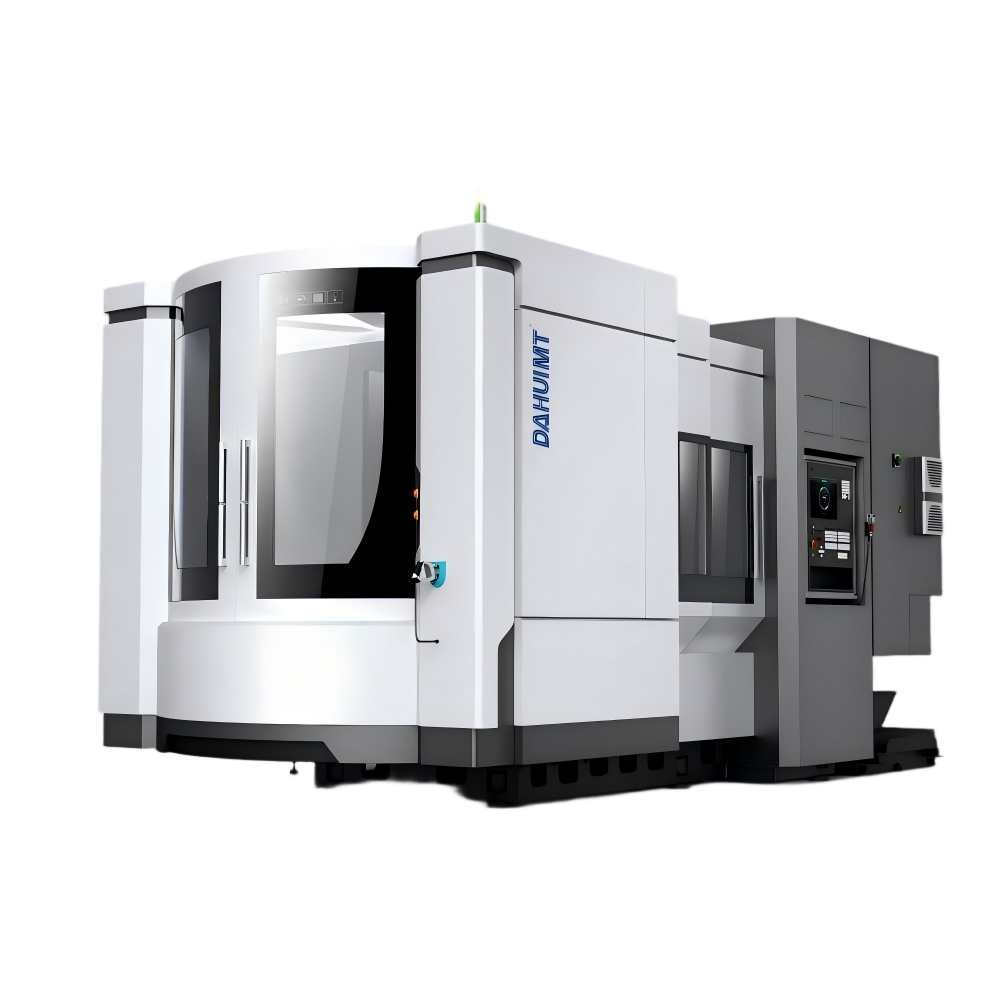

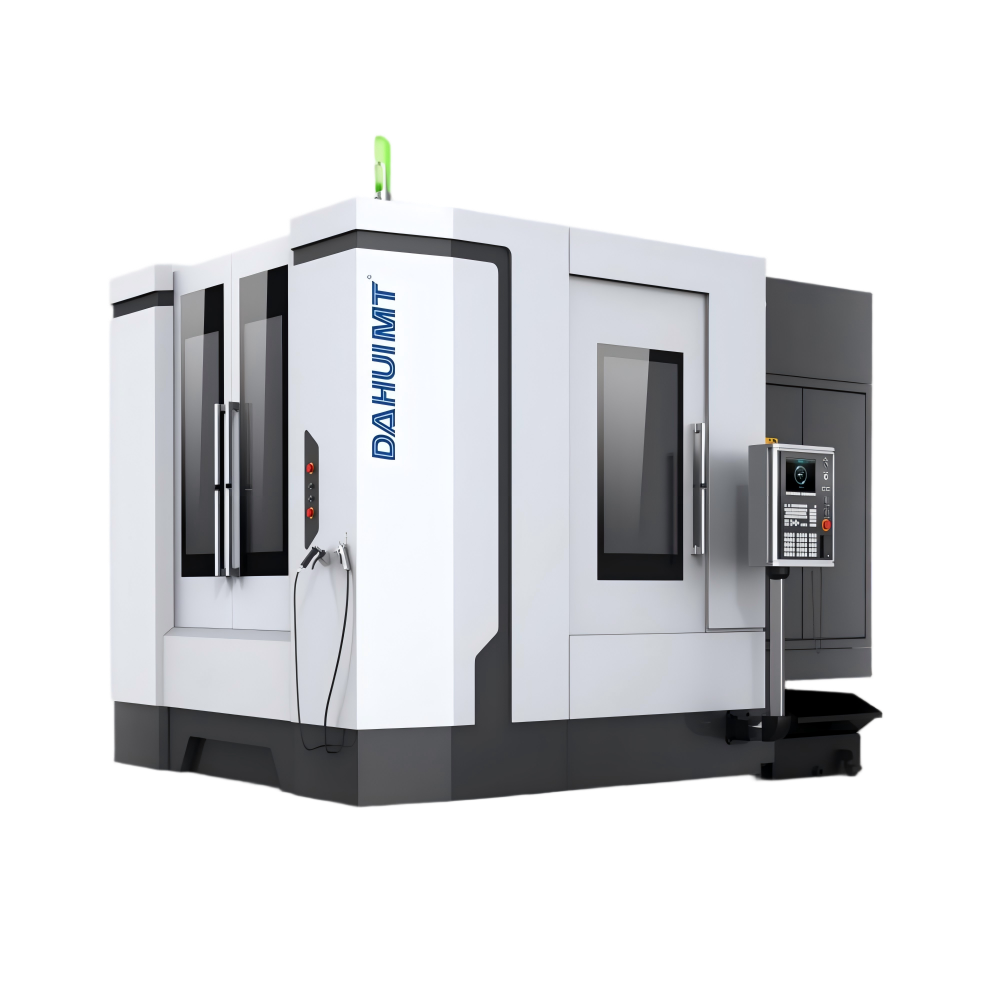

The DHL Series horizontal machining centers feature high-speed linear roller guides and automatic tool changers, enabling efficient milling, boring, drilling and tapping.

Table indexing: IT rotary table 1o *360/BRT rotary table 0.001*360

Spindle speed:4000/6000/8000/12000/15000 rpm

System: Siemens / Fanuc

Tool position:40/60/80/120

Expansion:4-axis linkage/measuring device/tool management/spindle internal cooling/normal pres-sure table/full closed-loop encoder

Customized models available

X/Y/Z Axis Travel (mm)

700/650/650

X/Y/Z Axis Rapid Traverse (m/min)

36/30/36

Positioning/Repeatability Accuracy (mm)

0.014/0.006

Load Capacity (Kg)

800

Overall Dimensions (mm)

3737×3400×3115

X/Y/Z Axis Travel (mm)

900/800/800

X/Y/Z Axis Rapid Traverse (m/min)

36/30/36

Positioning/Repeatability Accuracy (mm)

0.014/0.006

Load Capacity (Kg

1300

Overall Dimensions (mm)

3880×3785×3120

We would be happy to make an individual offer for you!

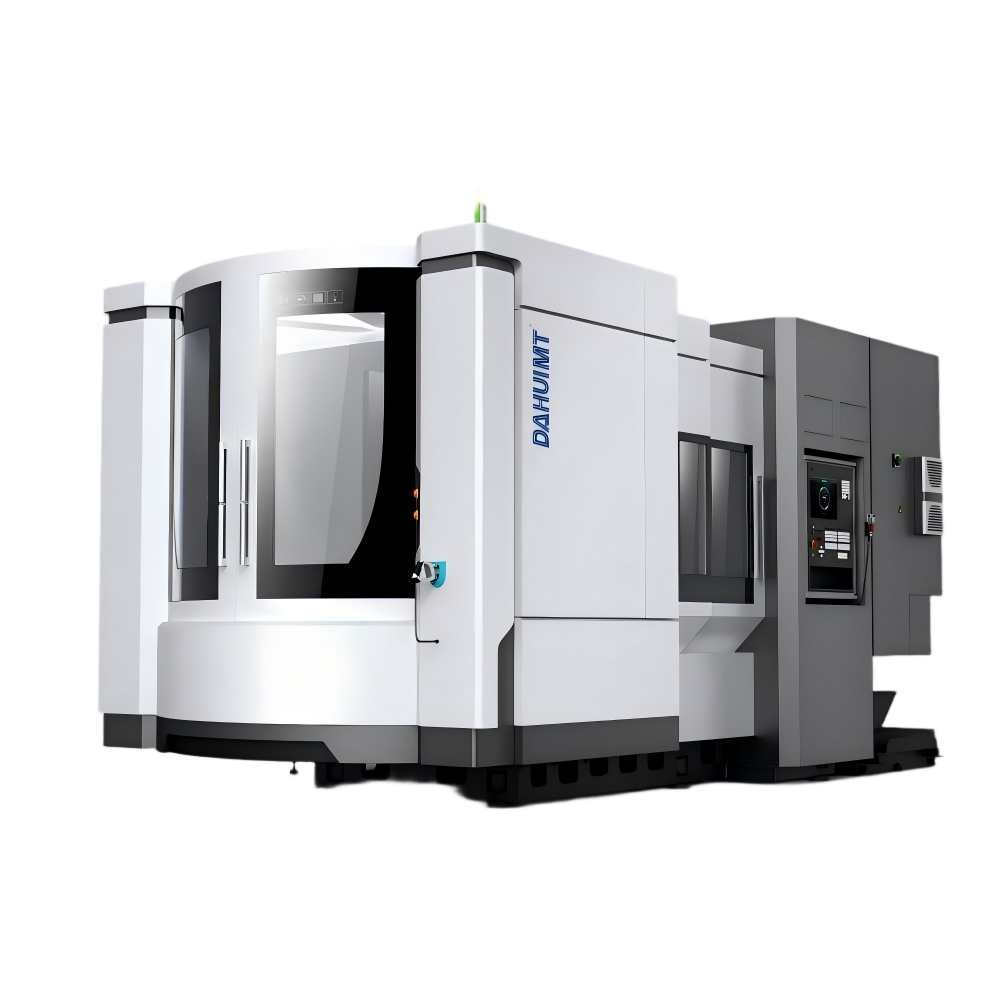

The DHM/DHA/DHL series all adopt high-rigidity structural designs (robust castings, optimized layouts), balancing overall stability and load-bearing capacity for heavy-duty machining.

All three series are equipped with high-performance spindles (hollow-cooled/high-speed types), tailored to match heavy cutting or high-precision machining requirements.

The DHM/DHA/DHL series feature customized high-response drive solutions, adapting to varied efficiency and load demands for different machining scenarios.

Relying on rigid structures, precision guideways and thermal compensation technologies, all three series maintain consistent machining stability and accuracy in long-term operation.

Each series is fitted with efficient cooling systems (hollow cooling/thermal management) and thermal compensation, preventing equipment thermal deformation.

The DHM/DHA/DHL series use mainstream CNC systems (FANUC/Siemens), ensuring user-friendly operation, strong compatibility and high control precision.

Collectively, the three series cover a wide machining range, meeting multi-face precision machining needs for large, medium-sized and complex parts (boxes, shells, etc.).

All series are configured with automatic tool changers (arm/chain-type), enabling seamless multi-process continuous machining and reducing non-cutting time.

Each series features efficient chip removal designs (horizontal spindle advantage + chip conveyors), promptly handling machining chips to keep production processes smooth.

The DHM/DHA/DHL series’ cutting fluid systems deliver precise supply, aiding cooling, chip removal and tool life extension during heavy or high-speed machining.