As a leading CNC lathe manufacturer in China, DAHUI MT offers a comprehensive range of CNC lathe series tailored to diverse machining needs: DHT series (high-precision slant bed type), DHCK61 series (flat bed type), DHCK52 series (heavy-duty horizontal type), DHCG51 series (precision vertical type), and VTC51 series (vertical turning and milling compound type). All models feature high-strength cast iron structures optimized via finite element analysis, delivering superior rigidity, stable cutting performance, and long-term precision retention. Equipped with reliable CNC systems (FANUC/Siemens/GSK/Mitsubishi), precision guideways (linear roller or hardened sliding types), and automated configurations (automatic tool turrets, chip conveyors), these lathes enable multi-process operations — turning, boring, milling, drilling, threading, and grooving — to meet complex machining requirements. Widely applied in automotive parts, aerospace components, wind power equipment, marine parts, and precision mechanical components, the series offer high automation, easy operation, and exceptional cost-performance ratio. Certified by CE, BV, and SGS, DAHUI MT serves customers in over 60 countries with flexible standard configurations and customized solutions, including non-standard structural designs, automated loading/unloading systems, and personalized process optimizations.

Horizontal Lathe -Slant Bed CNC Lathe

High-rigidity guideways, large workspace, accommodates special fixtures, AC servo motor + V-belt, excellent noise reduction

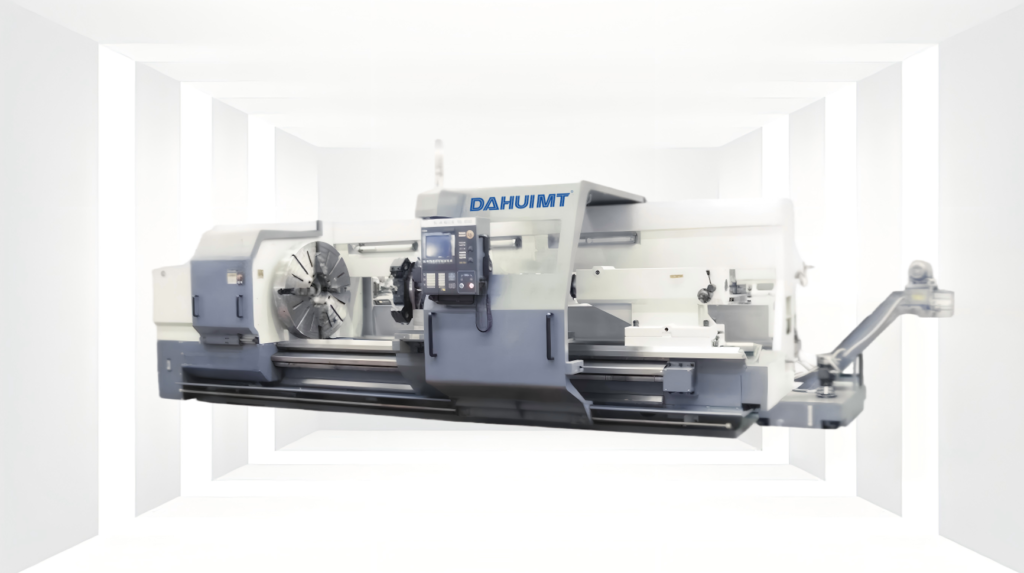

Horizontal Lathe -Flat Bed CNC Lathe

Complete specifications, suitable for processing various heavy-duty shafts and discs, wide application range, high-rigidity hardened guideways, integral casting, quenching process

Vertical Lathe – Double Column CNC Lathe

Lathes of this series adopt a gantry structure. The castings are cast using high-quality resin sand and lost foam casting process, with internal stress scientifically eliminated. The beam guides and ram guides are quenched by ultrasonic quenching treatment, and the sliding surfaces adopt paste plastic coating — which improves abrasion resistance by more than 5 times and enhances the precision retention of the guides.

Vertical Lathe – Single Column CNC Lathe

Used for roughing and finishing of internal and external cylindrical surfaces, end faces, grooves, holes, threads, and curved surfaces of medium, large, and heavy parts made of ferrous metals, non-ferrous metals, and some non-metallic materials.

Vertival Lathe- High Speed CNC Lathe

This machine accommodates high-speed steel tools, carbide tools, and various high-performance tools, processing workpieces made of ferrous metals, non-ferrous metals, and some non-metallic materials. It can complete rough and finish turning of internal/external cylindrical surfaces, internal/external conical surfaces, flat surfaces, and rotary curved surfaces, as well as grooving, threading, and other processes.