Rotary table speed:15/400rpm

Spindle speed:12000/15000/18000/24000rpmSystem:Siemens/Heidenhain

Tool position:40/60/80/120

Expansion:Measuring device/tool management/full closed-loop grating/graphite dedusting/ultrasonicmachining/3D model printing

Customized models available

We would be happy to make an individual offer for you!

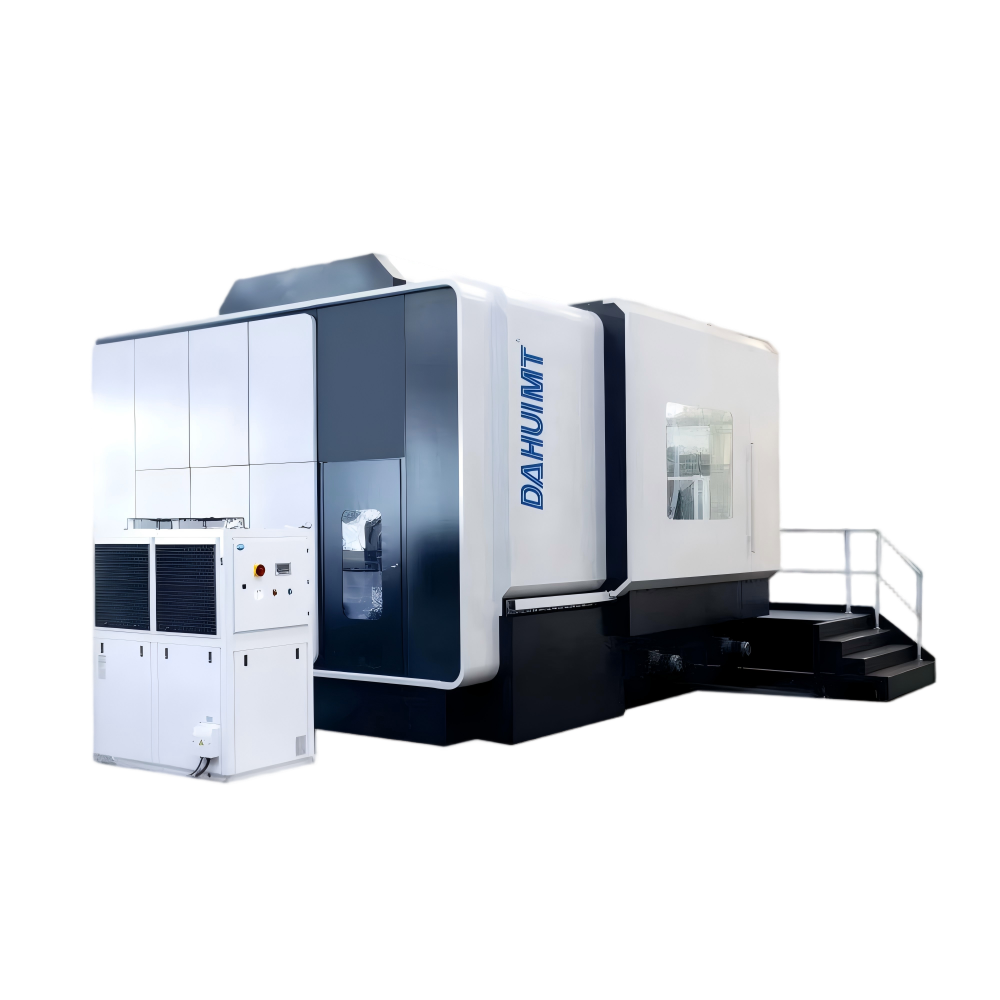

X/Y/Z Axis Travel (mm)

1000/1000/1000

X/Y/Z Axis Rapid Traverse (m/min)

60

Rotary Table Speed (rpm)

50

Positioning/Repeatability Accuracy (mm)

0.006/0.004

Load Capacity (Kg)

2000

Overall Dimensions (mm)

5300×5200×3600

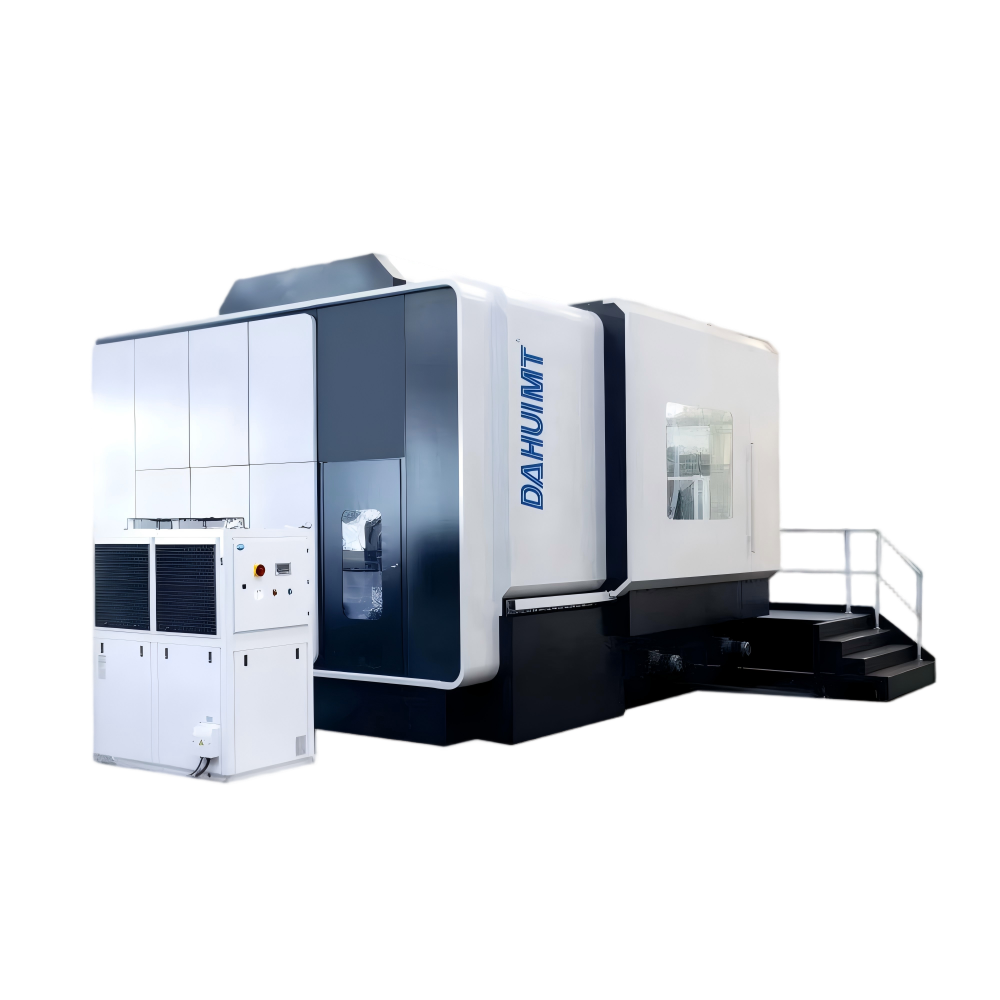

X/Y/Z Axis Travel (mm)

1250/1250/1000

X/Y/Z Axis Rapid Traverse (m/min)

60

Rotary Table Speed (rpm)

50

Positioning/Repeatability Accuracy (mm)

0.006/0.004

Load Capacity (Kg)

2500

Overall Dimensions (mm)

5500×6300×3700

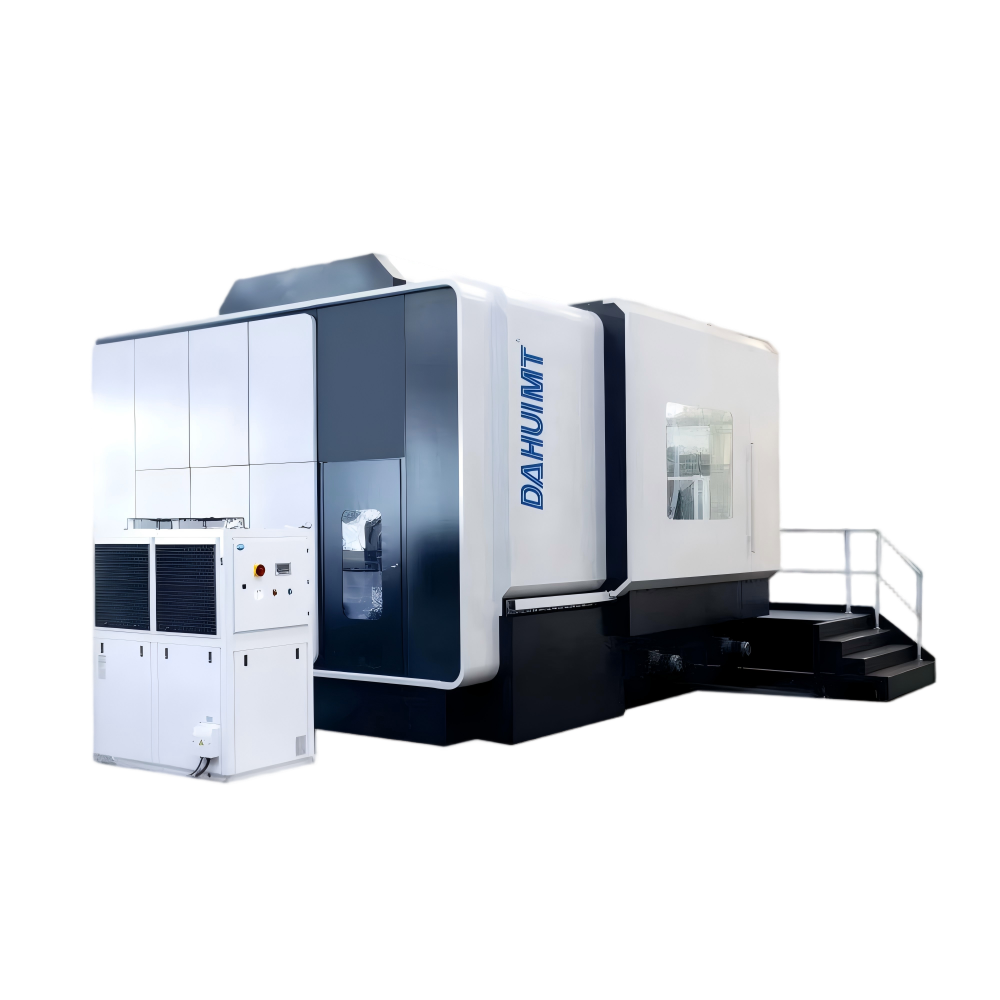

X/Y/Z Axis Travel (mm)

1350/1350/1000

X/Y/Z Axis Rapid Traverse (m/min)

60

Rotary Table Speed (rpm)

50

Positioning/Repeatability Accuracy (mm)

0.006/0.004

Load Capacity (Kg)

2500

Overall Dimensions (mm)

5600×6400×3700

X/Y/Z Axis Travel (mm)

1600/1600/1400

X/Y/Z Axis Rapid Traverse (m/min)

60/40/48

Rotary Table Speed (rpm)

15

Positioning/Repeatability Accuracy (mm)

0.006/0.004

Load Capacity (Kg)

4000

Overall Dimensions (mm)

6022×4955×3800

X/Y/Z Axis Travel (mm)

2100/2100/1700

X/Y/Z Axis Rapid Traverse (m/min)

40

Rotary Table Speed (rpm)

15

Positioning/Repeatability Accuracy (mm)

0.008/0.005

Load Capacity (Kg)

6000

Overall Dimensions (mm)

9600×8000×5300

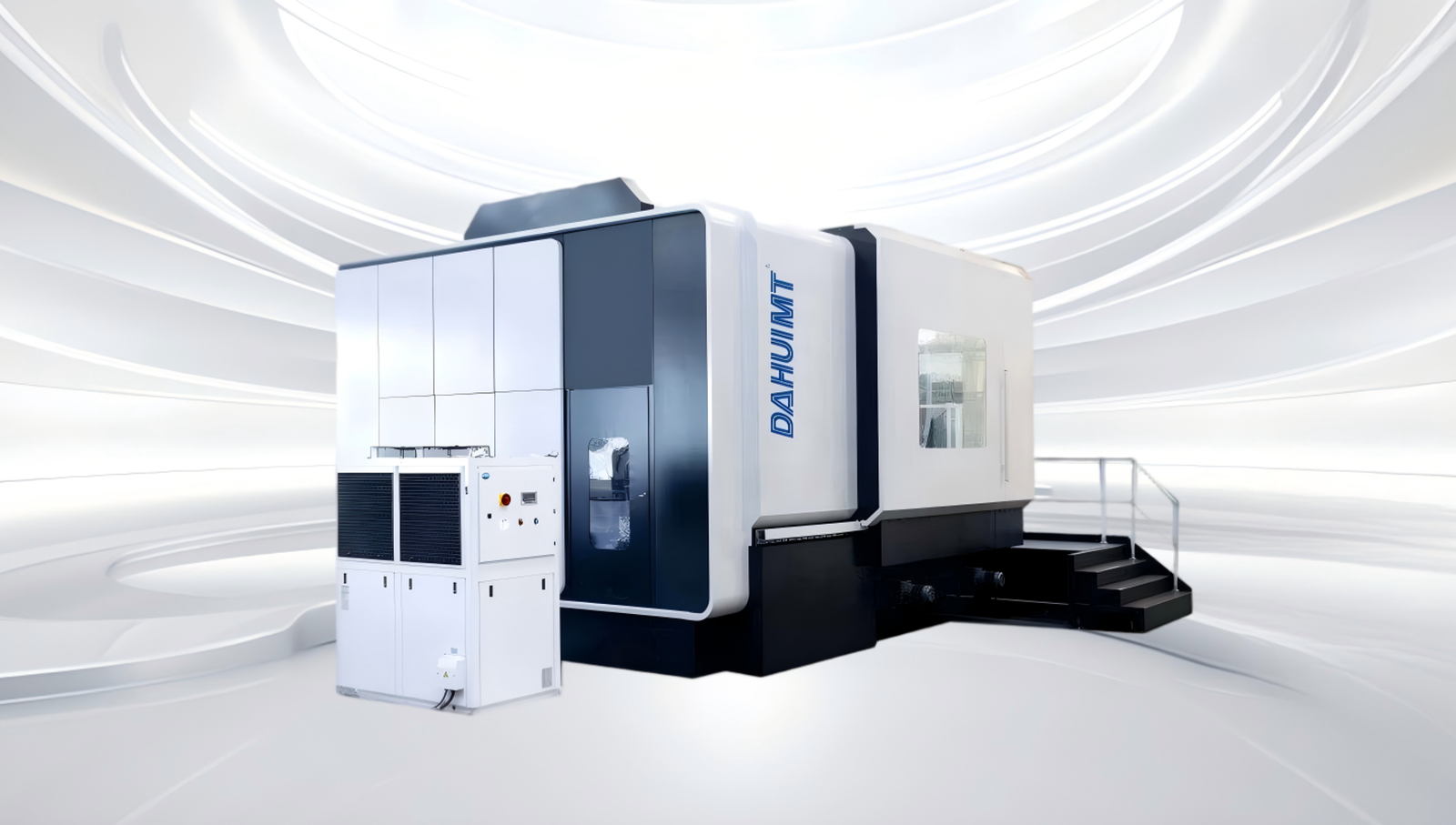

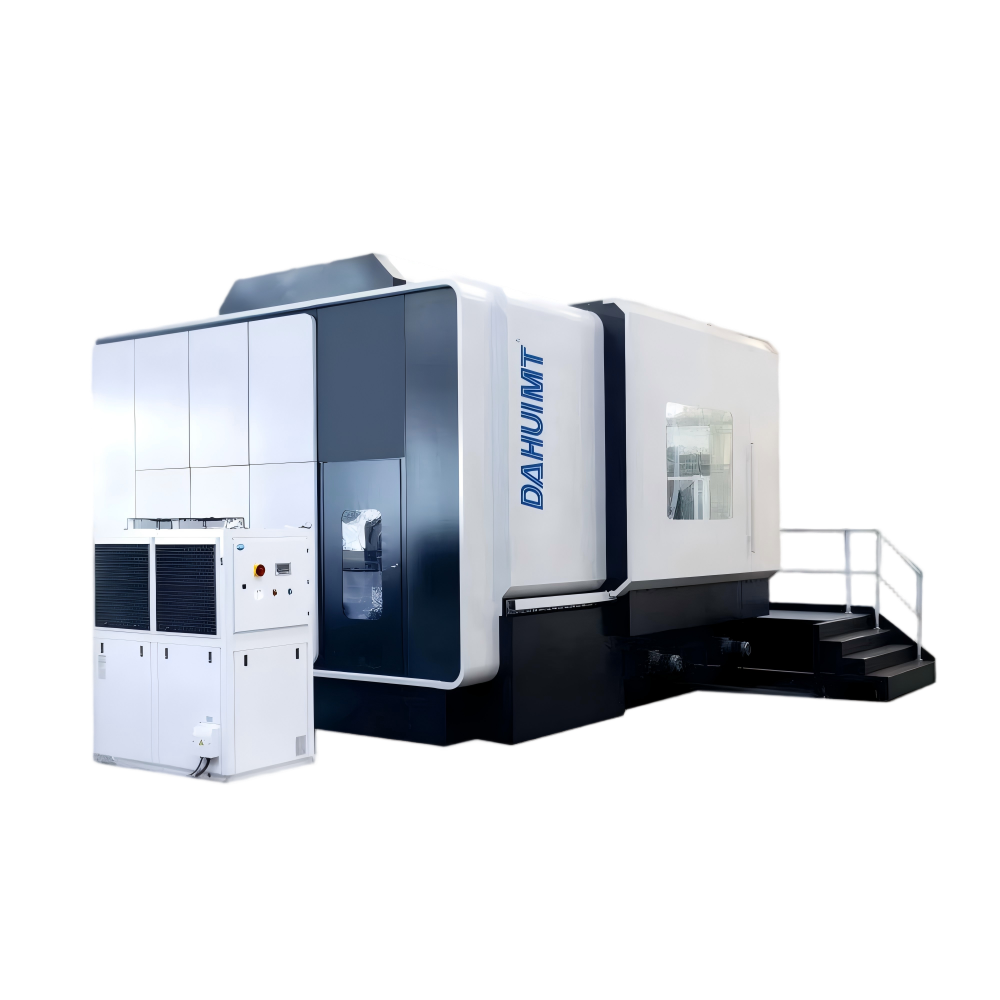

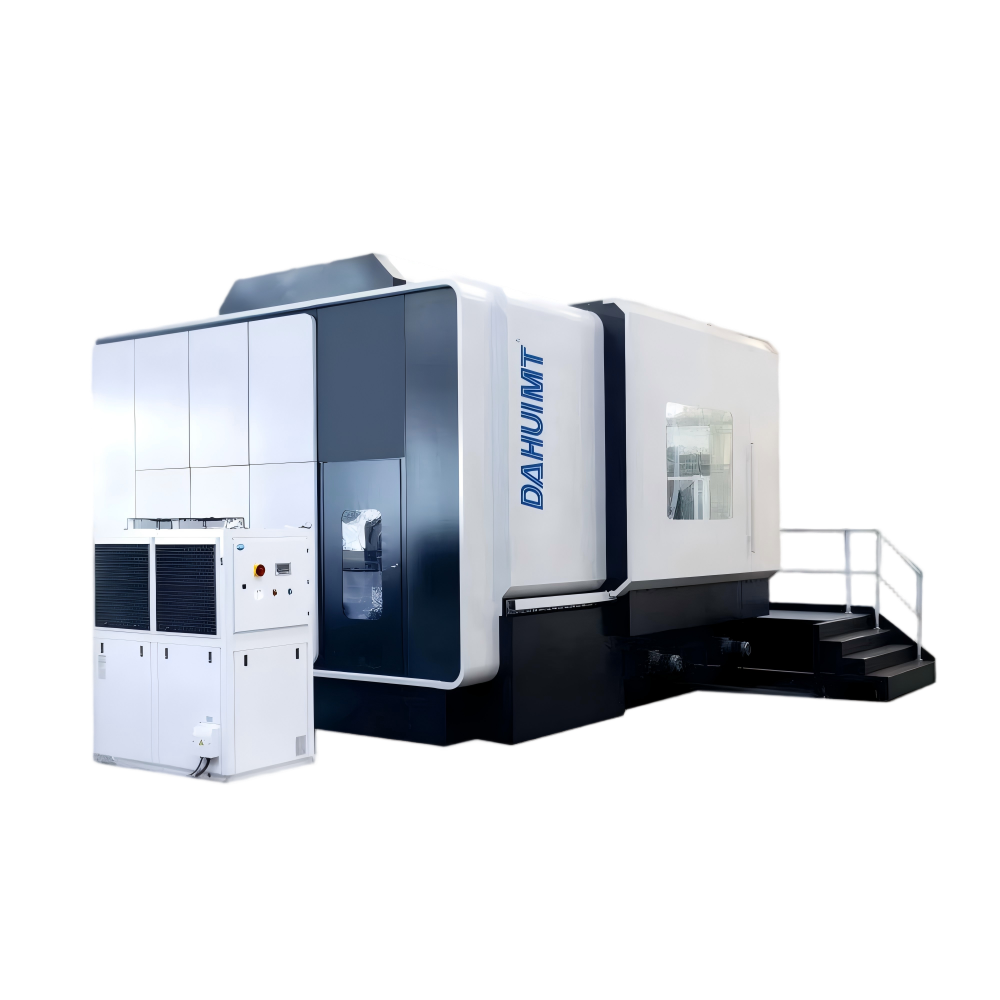

The DHW series adopts topology optimization for high-strength cast bed design, balancing structural rigidity and load-bearing capacity to support heavy-duty 5-axis machining.

The DHW series is equipped with high-torque motorized spindles, tailored to match its heavy cutting and large-load precision machining requirements.

The DHW series features customized high-response drive solutions, adapting to the efficiency needs of 5-axis linkage and heavy-duty machining scenarios.

Relying on rigid cast structures, rotary tables and excellent thermal stability, the DHW series maintains consistent stability and 0.006mm repeatability in long-term operation.

The DHW series is fitted with an efficient cooling system, supporting continuous heavy-duty machining by preventing equipment thermal deformation.

he DHW series uses mainstream CNC systems (FANUC/Siemens) with full closed-loop gratings, ensuring precise operation and strong compatibility.

The DHW series covers a wide range of large-scale machining needs, meeting multi-face 5-axis precision requirements for large molds, aerospace structures and heavy complex parts.

The DHW series is configured with suitable automatic tool magazine setups, enabling seamless multi-process continuous machining of heavy-duty complex parts.

The DHW series is equipped with a high-efficiency chip conveyor, promptly handling heavy cutting chips to keep the 5-axis machining process smooth.

The DHW series’ cutting fluid system delivers precise supply, aiding cooling, chip removal, and tool life extension during heavy-duty 5-axis machining.