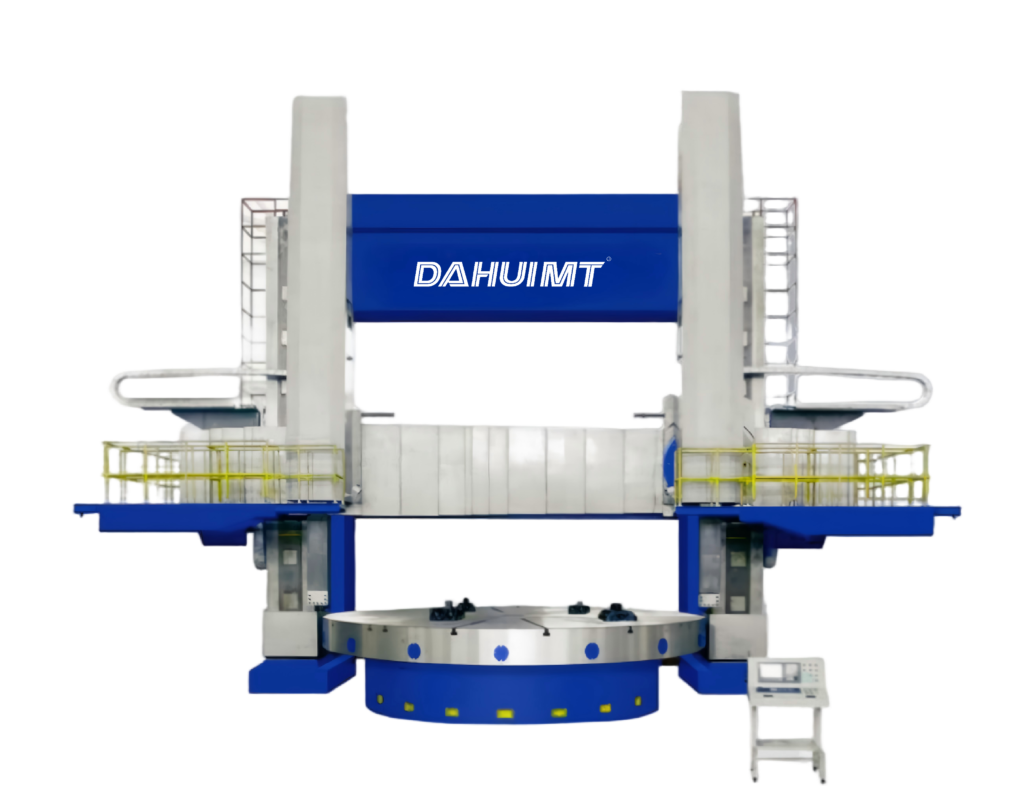

The DHCK52 Series heavy-duty CNC lathes feature horizontal layouts with high-strength cast structures and swing diameters up to 20000mm, supporting precision turning, boring, and milling of large shafts, discs, and cylinders. Equipped with Siemens/FANUC/Mitsubishi systems, high-torque spindles, and heavy-load tables, they deliver IT7 accuracy and robust cutting capability. Ideal for wind power, marine, oil equipment, and heavy machinery manufacturing, ensuring exceptional stability and thermal balance. Choose reliable ultra-heavy-duty CNC lathes for efficient precision machining of large heavy parts in high-end heavy-duty CNC turning applications.

Machining accuracy:IT7

System:Siemens/Fanuc/Mitsubishi/GSK/HNC

Expansion:Milling/grinding/measuring device/totally enclosed encoder

Customized models available

We would be happy to make an individual offer for you!

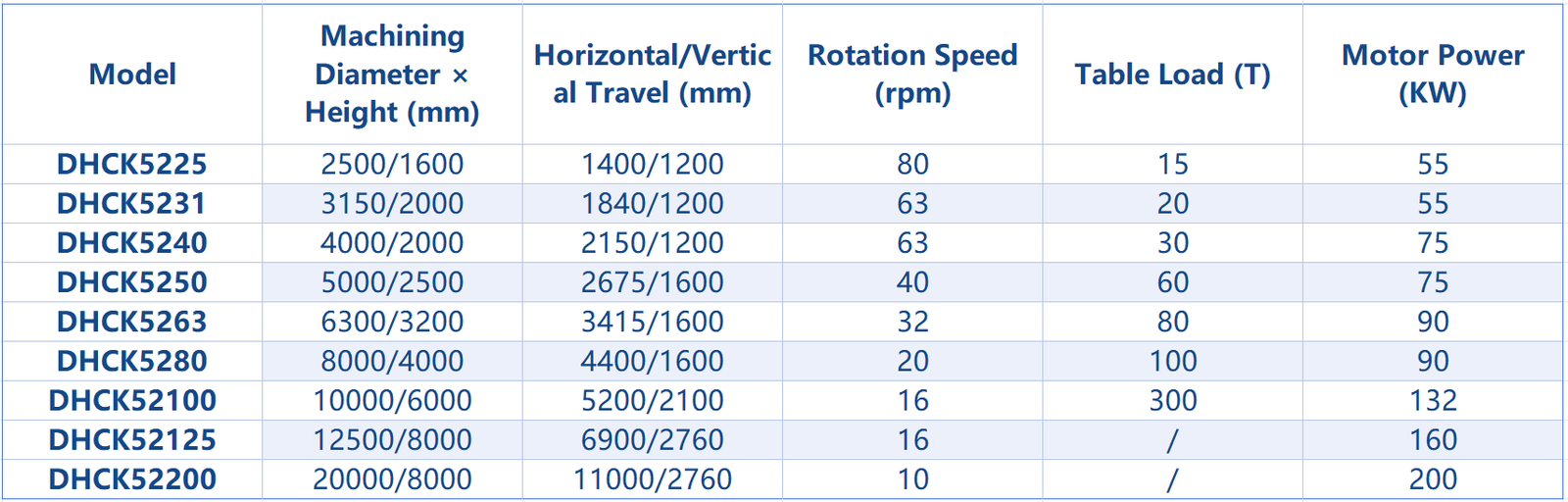

Machining Diameter × Height (mm)

2500/1600

Horizontal/Vertical Travel (mm)

1400/1200

Rotation Speed (rpm)

80

Table Load (T)

15

Motor Power (KW)

55

Machining Diameter × Height (mm)

3150/2000

Horizontal/Vertical Travel (mm)

1840/1200

Rotation Speed (rpm)

63

Table Load (T)

20

Motor Power (KW)

55

Machining Diameter × Height (mm)

4000/2000

Horizontal/Vertical Travel (mm)

2150/1200

Rotation Speed (rpm)

63

Table Load (T)

30

Motor Power (KW)

75

The DHCK52 series adopts topology optimization for high-strength cast horizontal structure design, balancing ultra-high rigidity and heavy-load bearing capacity to support precision turning, boring, and milling of large heavy shafts, discs, and cylinders.

The DHCK52 series is equipped with ultra-high-torque motorized spindles, tailored to match its heavy-duty cutting requirements, with spindle speeds ranging from 10rpm to 80rpm and motor power from 55KW to 200KW.

The DHCK52 series features customized high-stability AC servo drive solutions, adapting to the efficiency needs of heavy-duty turning, boring, and multi-process machining scenarios for large workpieces.

Relying on robust horizontal cast structures, precision guide systems and excellent thermal balance performance, the DHCK52 series maintains consistent stability and IT7-grade machining accuracy in long-term heavy-load operation.

The DHCK52 series is fitted with a high-performance lubrication and cooling system, supporting continuous heavy-duty machining by effectively controlling equipment and spindle thermal deformation.

The DHCK52 series uses mainstream CNC systems (Siemens/FANUC/Mitsubishi), ensuring precise operation, strong compatibility and reliable performance in heavy-load machining.

The DHCK52 series covers a wide range of ultra-heavy-duty machining needs, with machining diameter from 2500mm to 20000mm, horizontal/vertical travel up to 11000mm/2760mm, and table load capacity from 15T to 300T, meeting processing requirements for large heavy parts in key industries.

The DHCK52 series is configured with heavy-duty high-precision automatic tool turrets, enabling seamless multi-process continuous machining of turning, boring, and milling for large complex parts.

The DHCK52 series is equipped with a heavy-duty high-efficiency chip conveyor, promptly handling massive cutting chips to keep the ultra-heavy-duty precision machining process smooth.

The DHCK52 series’ cutting fluid system delivers large-flow precise supply, aiding cooling, chip removal, and tool life extension during heavy-duty cutting of difficult-to-process materials.