This series of CNC machine tools have full specifications and are suitable for roughing and finishing of small,medium, large and heavy shafts and disk workpieces in a wide range of applications. The guideway adoptsheavy-duty widening design and high rigidity hard rail, whole casting molding,quenching process.

Machining accuracy: IIT6~IT7

Chuck: manual/hydraulic 8-126 inches

Tool position:4/6/8/12

System:Siemens/Fanuc/Mitsubishi/GSKHNC

Distance between cen-ters:750/1000/1500/2000/3000/4000/5000/6000/8000/10,000/12,000/14,000/16,000mm

Expansion:Milling/grinding/measuring device Customized models available

We would be happy to make an individual offer for you!

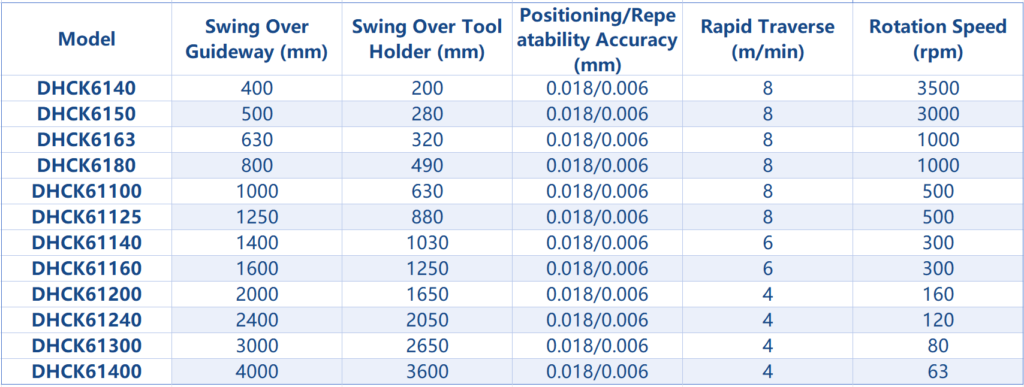

Swing Over Guideway (mm)

400

Swing Over Tool Holder (mm)

200

Positioning/Repeatability Accuracy (mm)

0.018/0.006

Rapid Traverse (m/min)

8

Rotation Speed (rpm)

3500

Swing Over Guideway (mm)

500

Swing Over Tool Holder (mm)

280

Positioning/Repeatability Accuracy (mm)

0.018/0.006

Rapid Traverse (m/min)

8

Rotation Speed (rpm)

3000

Swing Over Guideway (mm)

630

Swing Over Tool Holder (mm)

320

Positioning/Repeatability Accuracy (mm)

0.018/0.006

Rapid Traverse (m/min)

8

Rotation Speed (rpm)

1000

The DHCK61 series adopts topology optimization for high-rigidity flat bed design, balancing structural rigidity and load-bearing capacity to support medium-to-heavy-duty precision turning of shaft and disc parts.

The DHCK61 series is equipped with high-torque motorized spindles, tailored to match its stable medium-to-heavy-duty turning requirements, with spindle speeds ranging from 63rpm to 3500rpm.

The DHCK61 series features customized high-response AC servo drive solutions, adapting to the efficiency needs of precision turning, threading, and grooving scenarios.

Relying on rigid flat bed structures, precision guide systems and excellent thermal balance, the DHCK61 series maintains consistent stability and IT6-IT7 grade accuracy (positioning/repeatability accuracy up to 0.018/0.006mm) in long-term operation.

The DHCK61 series is fitted with an advanced lubrication and cooling system, supporting continuous medium-to-heavy-duty machining by preventing equipment and spindle thermal deformation.

The DHCK61 series uses mainstream CNC systems (FANUC/Siemens/GSK), ensuring precise operation, strong compatibility and user-friendly operation.

The DHCK61 series covers a wide range of medium-to-heavy-duty turning needs, with swing over guideway from 400mm to 4000mm and rapid traverse up to 8m/min, meeting processing requirements for internal/external cylinders, cones, threads and grooves of shaft/disc parts.

The DHCK61 series is configured with high-precision automatic tool turrets, enabling seamless multi-process continuous machining of turning, threading, and grooving.

The DHCK61 series is equipped with a high-efficiency chip conveyor, promptly handling turning chips to keep the medium-to-heavy-duty precision machining process smooth.

The DHCK61 series’ cutting fluid system delivers precise supply, aiding cooling, chip removal, and tool life extension during medium-to-heavy-duty turning.