Bed:40/45

Guide rail:Linear rail/hard rail/inclined rai/high and low parallel rail

Chuck:Manual/Hydraulic/Solid/Through-hole/6 -18inches

System:Siemens/Fanuc/Mitsubishi

Length:750/1000/1500/2000/3000mm

Expansion:Dual spindle/milling axis/Y-axis/dual turret/measuring device/tool setting instrument/fully enclosed encoder/spindle center outlet

Customized models available

We would be happy to make an individual offer for you!

Turning Diameter (mm)

480

Cutting Diameter (mm)

300

Positioning/Repeatability Accuracy (mm)

0.005/0.003

X/Z Axis Rapid Traverse (m/min)

30

Rotation Speed (rpm)

5000

Turning Diameter (mm)

580

Cutting Diameter (mm)

400

Positioning/Repeatability Accuracy (mm)

0.005/0.003

X/Z Axis Rapid Traverse (m/min)

30

Rotation Speed (rpm)

4000

Turning Diameter (mm)

680

Cutting Diameter (mm)

500

Positioning/Repeatability Accuracy (mm)

0.005/0.003

X/Z Axis Rapid Traverse (m/min)

30

Rotation Speed (rpm)

3500

Turning Diameter (mm)

920

Cutting Diameter (mm)

600

Positioning/Repeatability Accuracy (mm)

0.005/0.003

X/Z Axis Rapid Traverse (m/min)

24

Rotation Speed (rpm)

3000

Turning Diameter (mm)

1160

Cutting Diameter (mm)

700

Positioning/Repeatability Accuracy (mm)

0.005/0.003

X/Z Axis Rapid Traverse (m/min)

24

Rotation Speed (rpm)

2500

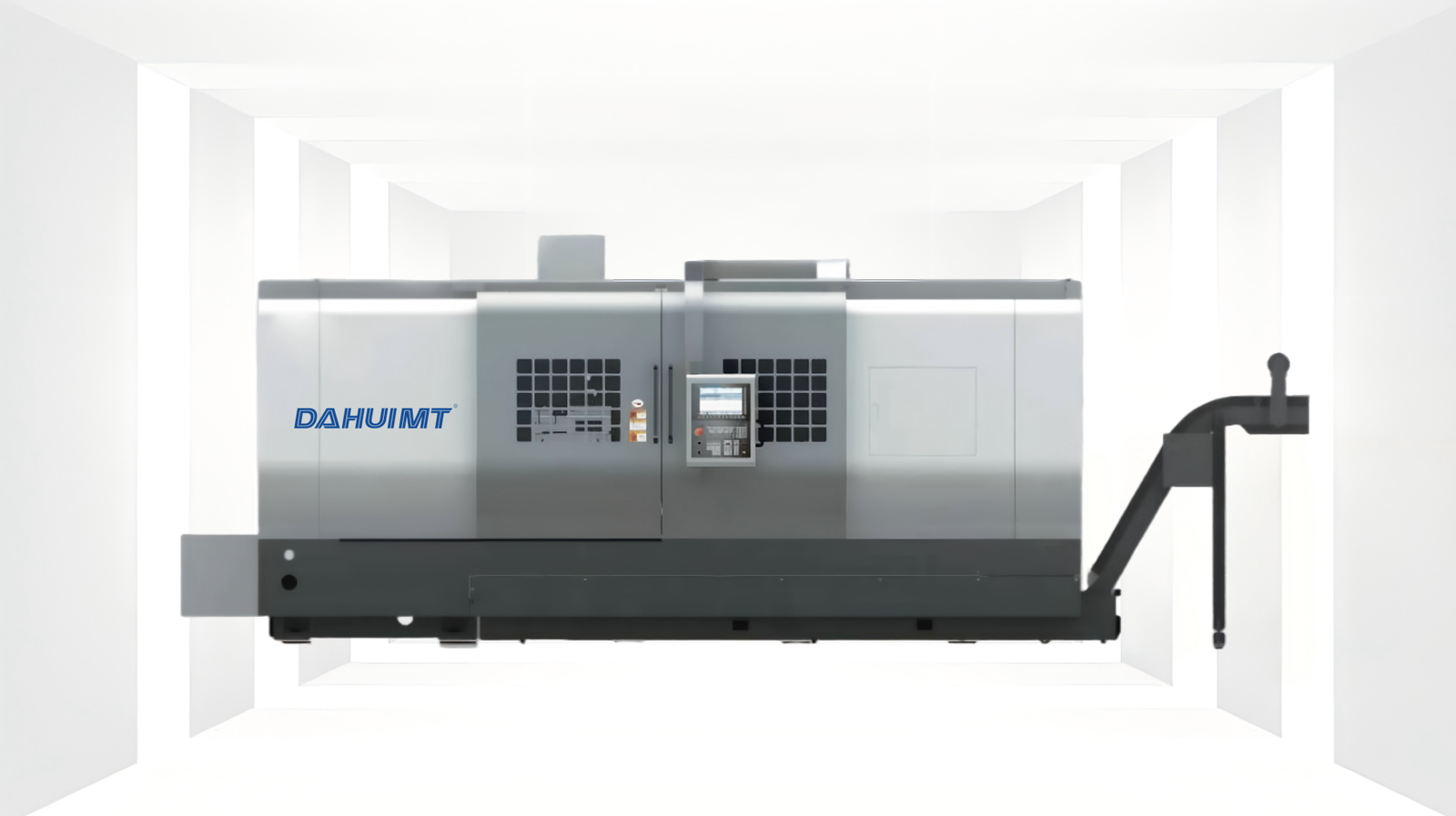

The DHT series adopts topology optimization for 40° inclined cast iron bed design, balancing structural rigidity and operational stability to support high-precision turning of shaft and disc parts.

The DHT series is equipped with high-torque motorized spindles, tailored to match its precision turning, drilling, and milling requirements, with spindle speeds ranging from 2500rpm to 5000rpm.

The DHT series features customized high-response AC servo drive solutions, adapting to the efficiency needs of high-speed precision turning and multi-process machining scenarios.

Relying on inclined cast iron bed structures, linear guideways and low-friction design, the DHT series maintains consistent stability and superior positioning/repeatability accuracy (up to 0.005/0.003mm) in long-term operation.

The DHT series is fitted with an advanced spindle cooling system, supporting continuous high-precision machining by preventing equipment and spindle thermal deformation.

The DHT series uses mainstream CNC systems (FANUC/Siemens), ensuring precise operation, strong compatibility and user-friendly operation.

The DHT series covers a wide range of precision turning needs, with turning diameters from 480mm to 1160mm and X/Z axis rapid traverse up to 30m/min, meeting processing requirements for shaft and disc parts of various sizes.

The DHT series is configured with high-precision automatic tool turrets, enabling seamless multi-process continuous machining of turning, drilling, and milling.

The DHT series is equipped with a high-efficiency chip conveyor, promptly handling turning chips to keep the high-precision machining process smooth.

The DHT series’ cutting fluid system delivers precise supply, aiding cooling, chip removal, and tool life extension during high-speed precision turning.