The XKW23 Series Fixed-Beam CNC Gantry Boring and Milling Machine is one of the fixed-beam CNC gantry boring and milling machines independently developed and manufactured by our company. It is ideal for precision boring, milling, drilling, and tapping of large structures, boxes, and molds, demonstrating outstanding stability (backed by its high-rigidity fixed-beam gantry frame and precision roller guides) as well as IT7 machining accuracy and heavy-load cutting performance.

Spindle speed:3500/4000/6000rpm

Z-axis form:T-rail/ram

Spindle drive:Gearbox/direct coupled spindle

Operating system: Siemens/Fanuc

Number of tools:24/32/40/60/80

Machining Expansion:Measuring Device/Tool Setting Instrument/Full Closed Loop Encoder/Fourth

Axis/Spindle Center Outflow/Accessory Heads

Customized models available

We would be happy to make an individual offer for you!

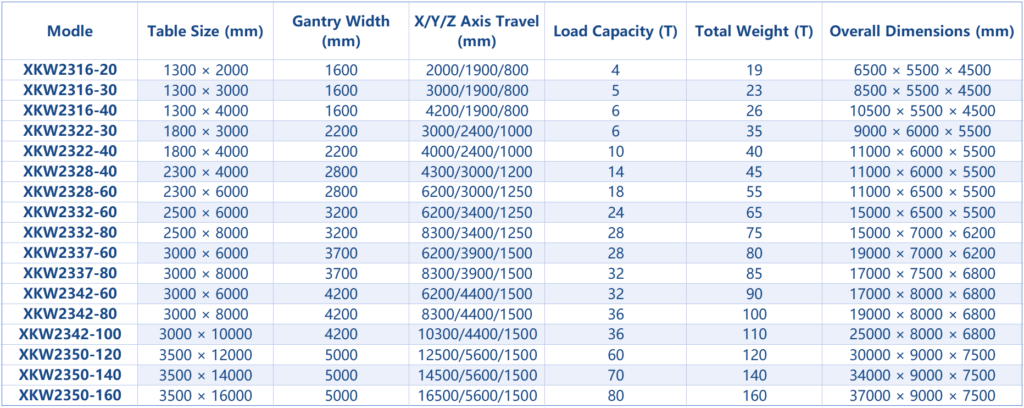

Table Size (mm):1300×2000

Gantry Width (mm):1600

X/Y/Z Axis Travel (mm):2000/1900/800

Load Capacity (T):4

Total Weight (T):19

Overall Dimensions (mm):6500×5500×4500

Table Size (mm):1300×2000

Gantry Width (mm):1600

X/Y/Z Axis Travel (mm):2000/1900/800

Load Capacity (T):4

Total Weight (T):19

Overall Dimensions (mm):6500×5500×4500

Table Size (mm):1300×2000

Gantry Width (mm):1600

X/Y/Z Axis Travel (mm):2000/1900/800

Load Capacity (T):4

Total Weight (T):19

Overall Dimensions (mm):6500×5500×4500

Table Size (mm):1800×3000

Gantry Width (mm):2200

X/Y/Z Axis Travel (mm):3000/2400/1000

Load Capacity (T):6

Total Weight (T):25

Overall Dimensions (mm):9000×6000×5500

Table Size (mm):1800×3000

Gantry Width (mm):2200

X/Y/Z Axis Travel (mm):3000/2400/1000

Load Capacity (T):6

Total Weight (T):25

Overall Dimensions (mm):9000×6000×5500

Table Size (mm):1800×3000

Gantry Width (mm):2200

X/Y/Z Axis Travel (mm):3000/2400/1000

Load Capacity (T):6

Total Weight (T):25

Overall Dimensions (mm):9000×6000×5500

Table Size (mm):2300×6000

Gantry Width (mm):2800

X/Y/Z Axis Travel (mm):6200/3000/1250

Load Capacity (T):18

Total Weight (T):55

Overall Dimensions (mm):11000×6500×5500

Table Size (mm):2500×6000

Gantry Width (mm):3200

X/Y/Z Axis Travel (mm):6200/3400/1250

Load Capacity (T):24

Total Weight (T):65

Overall Dimensions (mm):15000×6500×5500

Table Size (mm):3000×10000

Gantry Width (mm):4200

X/Y/Z Axis Travel (mm):10300/4400/1500

Load Capacity (T):36

Total Weight (T):110

Overall Dimensions (mm):25000×8000×6800

The XKW series adopts topology optimization for gantry and bed design, balancing structural rigidity and load-bearing capacity to support heavy-duty large-scale machining.

The XKW series is equipped with high-power, high-torque motorized spindles, tailored to match its heavy-load cutting and efficient material removal requirements.

The XKW series features customized high-response drive solutions, adapting to the efficiency needs of multi-axis linkage and large-stroke machining scenarios.

Relying on rigid gantry structures, precision roller guides and excellent thermal stability, the XKW series maintains consistent stability and IT7-level accuracy in long-term operation.

Our efficient machine cooling concept includes the cooling of the power train, control cabinet, motorized spindle, rotary table and cutting fluid system, whereby a high level of accuracy is achieved on the part.

Working with familiar control system with choice between SIEMENS machine controls.

The XKW series covers a wide range of large-scale machining needs, with travels up to tens of meters and worktables up to 5000×20000 mm, meeting precision requirements for large structures, boxes and molds.

The XKW series is configured with suitable automatic tool magazine setups, enabling seamless multi-process continuous machining of large heavy parts.

The XKW series is equipped with a high-efficiency chip conveyor, promptly handling heavy cutting chips to keep the large-scale machining process smooth.

The XKW series’ cutting fluid system delivers precise supply, aiding cooling, chip removal, and tool life extension during heavy-duty gantry machining.