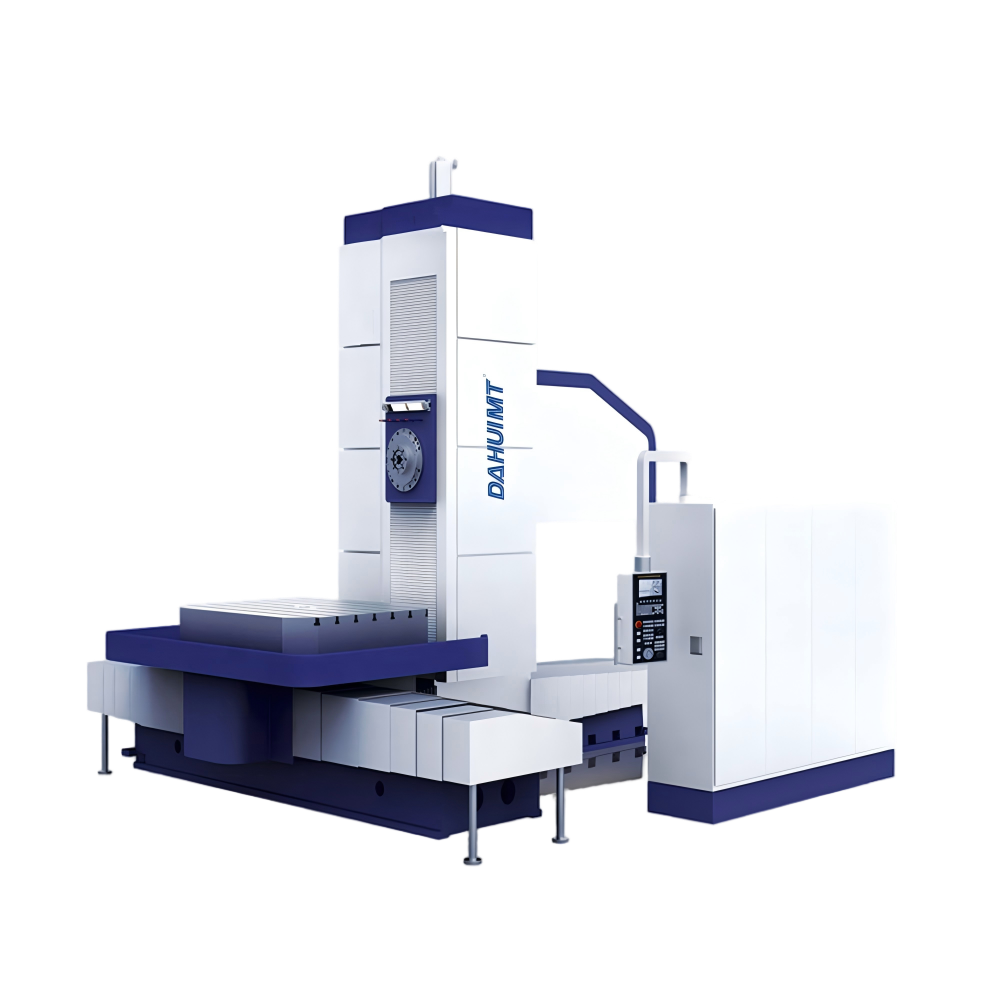

This series of machine tools adopts a T-type high-rigidity bed structure, featuring multiple supports and composite guideways with unloading devices. It offers high precision, high torque, high load capacity, and high flexibility, along with high-speed and quiet operation.

W-axis travel:800/1000/1500mm

Ram form: square ram / with compensation mechanism

Operating system:Siemens/Fanuc

Processing Expansion:Automatic Tool Magazine/Measuring Device/Tool Setting Instrument/FullClosed Loop Optical Encoder/Spindle Center Outflow/Accessory Head/Heavy Duty Roller LinearGuideway

Customized models available

We would be happy to make an individual offer for you!

X/Y/Z/W Axis Travel (mm)

3000/2000/1600/800

Positioning/Repeatability Accuracy (mm)

0.02/0.015

Rapid Traverse (mm/min)

10000

Boring Spindle Diameter (mm)

130

Table Size (mm)

1600×2000

Table Load Capacity (T)

10

X/Y/Z/W Axis Travel (mm)

4000/2000/800/1500

Positioning/Repeatability Accuracy (mm)

0.02/0.015

Rapid Traverse (mm/min)

8000

Boring Spindle Diameter (mm)

130

Table Size (mm)

1600×1800

Table Load Capacity (T)

10

X/Y/Z/W Axis Travel (mm)

3000/2500/1600/1000

Positioning/Repeatability Accuracy (mm)

0.02/0.015

Rapid Traverse (mm/min)

10000

Boring Spindle Diameter (mm)

160

Table Size (mm)

2500×2500

Table Load Capacity (T)

20

X/Y/Z/W Axis Travel (mm)

4000/3000/900/1500

Positioning/Repeatability Accuracy (mm)

0.02/0.015

Rapid Traverse (mm/min)

8000

Boring Spindle Diameter (mm)

160

Table Size (mm)

2000×2000

Table Load Capacity (T)

20

High-precision slant-bed DHT: efficient shaft/disc machining.

The TK65/TK65A series adopts topology optimization for high-rigidity planer-type integral cast structure design, balancing exceptional rigidity and heavy-load bearing capacity to support precision boring, milling, drilling, and tapping of large boxes, frames, and heavy parts.

The TK65/TK65A series is equipped with high-torque motorized spindles, tailored to match its heavy-duty cutting requirements, with boring spindle diameters of 130mm or 160mm for efficient material removal.

The TK65/TK65A series features customized high-response multi-axis CNC servo drive solutions, adapting to the efficiency needs of multi-axis linkage and large-stroke machining scenarios for large workpieces.

Relying on robust planer cast structures, precision guide systems and excellent vibration resistance, the TK65/TK65A series maintains consistent stability and IT7-grade machining accuracy (positioning/repeatability accuracy up to 0.02/0.015mm) in long-term heavy-load operation.

The TK65/TK65A series is fitted with an advanced lubrication and cooling system, supporting continuous heavy-duty machining by effectively controlling equipment and spindle thermal deformation.

The TK65/TK65A series uses mainstream CNC systems (Siemens/FANUC), ensuring precise multi-axis linkage, strong compatibility and reliable performance in heavy-duty boring and milling.

The TK65/TK65A series covers a wide range of heavy-duty machining needs, with X/Y/Z/W axis travel up to 4000/3000/1600/1500mm, table size up to 2500×2500mm, and table load capacity up to 20T, meeting processing requirements for large structural parts in aerospace, heavy machinery and mold industries.

The TK65/TK65A series is configured with high-precision tool holders and multi-process machining capabilities, enabling seamless continuous machining of boring, milling, drilling, and tapping.

The TK65/TK65A series is equipped with a heavy-duty high-efficiency chip conveyor, promptly handling massive cutting chips to keep the heavy-duty precision machining process smooth.

The TK65/TK65A series’ cutting fluid system delivers large-flow precise supply, aiding cooling, chip removal, and tool life extension during heavy-duty boring and milling of large parts.