YK31 Series features a vertical layout with high rigidity and precision. It handles gears up to 16000mm in diameter, ideal for automotive and engineering sectors, with customizable options.

Configuration: Protection/hydraulic/oil mist collection/tool spindle

Number of CNC axes:2/4/5/6

Machining accuracy: 7-8 grade

System:Siemens/FanucExpansion:Fixture/tooling/intemal teeth

Customized models available

We would be happy to make an individual offer for you!

Table Diameter (mm)

280

Max. Diameter (mm)

200

Modulus (mm)

8

Tooth Width (mm)

250

Weight (T)

4.5

Table Diameter (mm)

370

Max. Diameter (mm)

320

Modulus (mm)

8

Tooth Width (mm)

300

Weight (T)

6.3

Table Diameter (mm)

360

Max. Diameter (mm)

360

Modulus (mm)

10

Tooth Width (mm)

450

Weight (T)

14

The YK31 series adopts topology optimization for high-rigidity integral cast structure design, balancing exceptional rigidity and stable load-bearing capacity to support precision hobbing of internal/external spur gears, helical gears, and worms.

The YK31 series is equipped with high-torque motorized spindles, tailored to match its gear hobbing requirements for various moduli, with spindle speeds optimized for efficient gear forming and stable cutting performance.

The YK31 series features customized multi-axis CNC servo drive solutions, adapting to the efficiency needs of high-precision gear hobbing and batch production scenarios.

Relying on robust integral cast structures, precision guide systems and excellent vibration damping performance, the YK31 series maintains consistent stability and 7-8 grade gear machining accuracy in long-term operation.

The YK31 series is fitted with a dedicated lubrication and cooling system, supporting continuous batch machining by effectively controlling equipment and spindle thermal deformation.

The YK31 series uses mainstream CNC systems (FANUC/Siemens), ensuring precise multi-axis linkage, strong compatibility and reliable performance in high-precision gear hobbing.

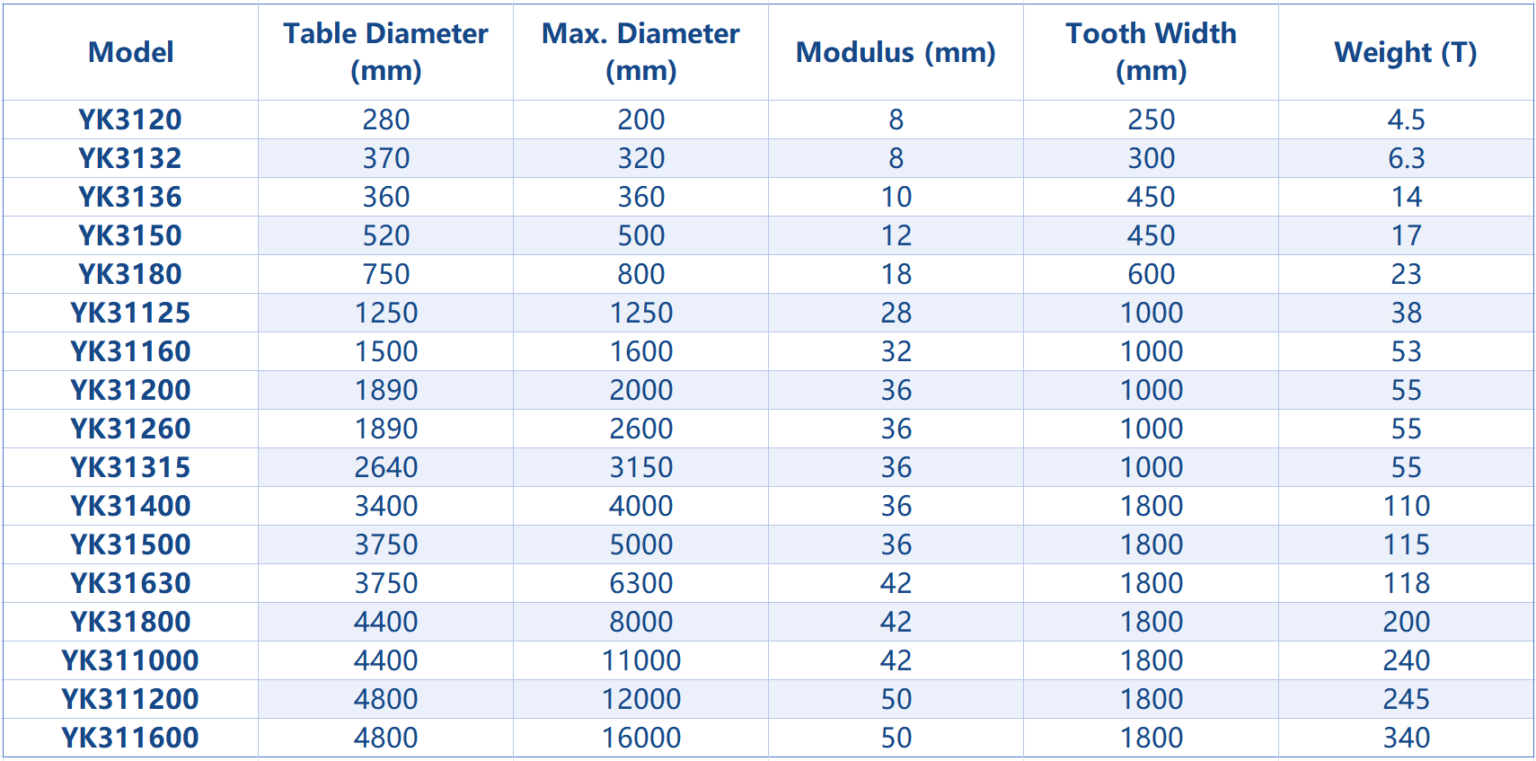

The YK31 series covers a wide range of gear machining needs, with maximum gear diameter from 200mm to 16000mm, modulus range from 8mm to 50mm, and table load capacity up to corresponding specifications, meeting processing requirements for gears in automotive, aerospace and heavy machinery industries.

The YK31 series is configured with high-precision hobbing tool holders, enabling seamless gear hobbing of internal/external gears and worms with consistent accuracy.

The YK31 series is equipped with a high-efficiency chip conveyor, promptly handling gear cutting chips to keep the precision hobbing process smooth.

The YK31 series’ cutting fluid system delivers targeted precise supply, aiding cooling, chip removal, and tool life extension during high-precision gear hobbing.