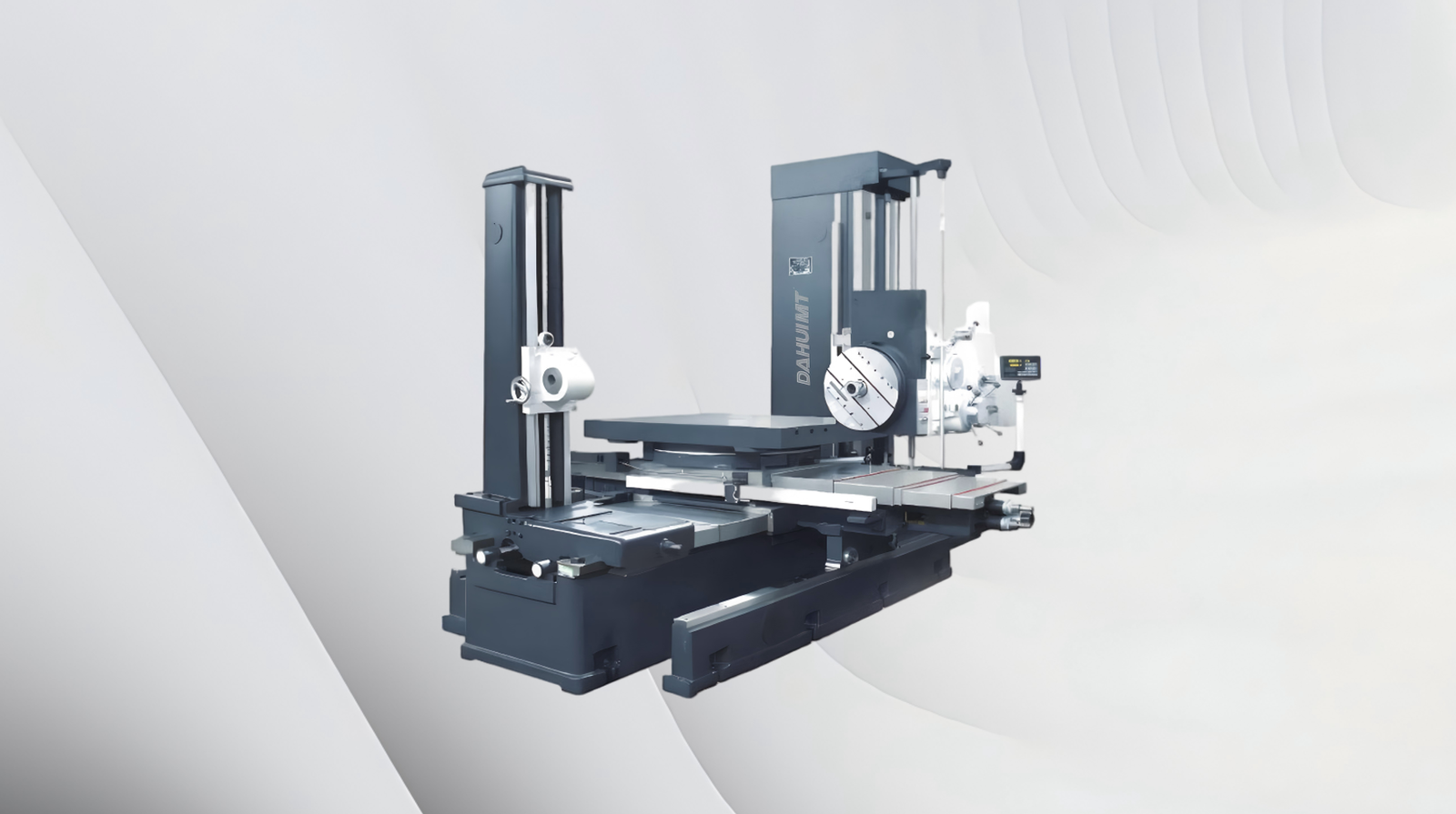

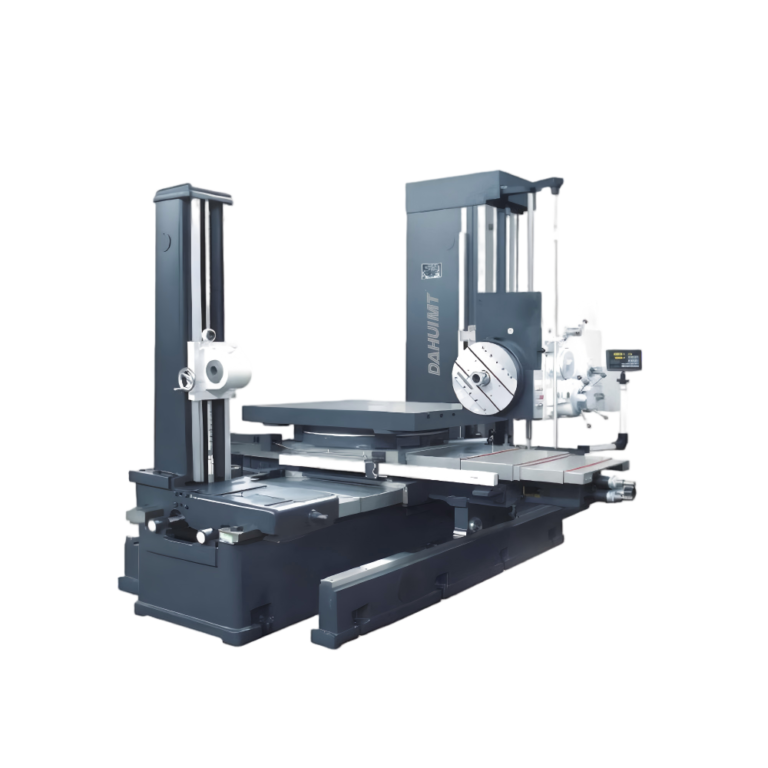

The TPX series (TPX6113/2, TPX6111B, etc.) are high-rigidity horizontal boring machines, offering IT7 precision for large parts in aerospace/heavy machinery, with robust spindles and versatile travels.

MAIN CONFIGURATION:

1.Main transmission system(AC main motor, change speed motor, Boring axis)

2.X/Y axis dragging system( motor, screw)

3.Main parts (bed、column, driven head, worktable)

4.Electrical system (electrical box、 PLC、 display).

5.Hydraulic system(include motor, pump, pressure control valve)

6.Automatic lubrication system(including in motor, pump, distributor)

We would be happy to make an individual offer for you!

| Specification Item | Unit | TPX6113/2 | TPX6113 | TPX6111B | TPX6111B/2 | TPX6111B/3 |

| Spindle diameter | mm | ϕ130 | ϕ130 | ϕ110 | ϕ110 | ϕ110 |

| Max. spindle torque | N.m | 3136 | 3136 | 1225 | 1225 | 1225 |

| Max. facing slide torque | N.m | 4900 | 4900 | 1960 | 1960 | 1960 |

| Max. spindle axial thrust | N | 31360 | 31360 | 12250 | 12250 | 12250 |

| Spindle taper | — | Metric 80 | Metric 80 | morse 6 (7:24, 50#) ISO50 7:24 |

morse 6 (7:24, 50#) ISO50 7:24 |

morse 6 (7:24, 50#) ISO50 7:24 |

| Max. spindle travel | mm | 900 | 900 | 600 | 600 | 600 |

| Max. radial facing slide travel | mm | 250 | 250 | 180 | 180 | 180 |

| Max. permissible table load | Kg | 10000 | 8000 | 2500 | 2500 | 3000 |

| Radial facing slide speed steps | steps | 18 | 18 | 18 | 18 | 18 |

| Radial facing slide speed range | r/min | 2.5–125 | 2.5–125 | 4–200 | 4–200 | 4–200 |

|

Rapid traverse speed (spindle/headstock/cross/longitudinal) |

mm/min |

2500 |

2500 |

2500 |

2500 |

2500 |

| Spindle speed steps | steps | 24 | 24 | 22 | 22 | 22 |

| Spindle speed range | r/min | 4–800 | 4–800 | 8–1000 | 8–1000 | 8–1000 |

| Facing head diameter | mm | 800 | 800 | 600 | 600 | 600 |

| Worktable size | mm | 1600×1800 | 1400×1600 | 960×1100 | 1200×1400 | 1300×1600 |

| Worktable rotation angle | ° | 360° | 360° | 360° | 360° | 360° |

| Worktable transverse travel (X-axis) | mm | 2000 | 2000 | 900 | 1250 | 1600 |

| Headstock travel (Y-axis) | mm | 1800 | 1500 | 1000 | 1100 | 1300 |

| Table horizontal travel (Z-axis) | mm | 2000 | 1800 | 1000 | 1000 | 1400 |

| Main motor power | kw | 15 | 5 | 7.5 | 7.5 | 7.5 |

| Weight | kg | 28000 | 25300 | 13000 | 14500 | 18000 |

| Overall dimensions | mm | 7030×4665×3800 | 6995×3647×3442 | 4910×2454×2750 | 4930×3359×2750 | 5117×3359×3079 |

The YK31 series provides our customers with a machine that ensures precise, reliable, and efficient gear machining processes.

The TPX series adopts topology optimization for high-rigidity integral cast structure design, balancing exceptional rigidity and stable load-bearing capacity to support precision turning of inner/outer cylindrical surfaces, conical faces, end faces, grooves, and threads for medium-to-large workpieces.

The TPX series is equipped with high-torque servo-driven spindles, tailored to match its efficient turning requirements for various mechanical parts, with spindle speeds optimized for stable cutting performance and motor power configured to meet medium-to-heavy-duty machining needs.

The TPX series features customized high-response AC servo drive solutions, adapting to the efficiency needs of high-speed precision turning, threading, grooving and batch production scenarios.

Relying on robust integral cast structures, precision guide systems and excellent thermal stability, the TPX series maintains consistent stability and IT6-IT7 grade accuracy (surface finish up to Ra 1.6 μm) in long-term continuous operation.

The TPX series is fitted with an advanced lubrication and cooling system, supporting continuous batch machining by effectively preventing equipment and spindle thermal deformation.

The TPX series uses mainstream CNC systems (FANUC/Siemens/GSK), ensuring precise operation, strong compatibility and user-friendly operation for versatile machining needs.

The TPX series covers a wide range of precision turning needs, with turning diameter matching medium-to-large workpiece specifications, machining height up to corresponding standards, and workpiece load capacity adapted to industrial application requirements, meeting processing needs for automotive parts, flanges, brake discs, and general mechanical components.

The TPX series is configured with high-precision automatic tool turrets (multi-station options), enabling seamless multi-process continuous machining of turning, grooving, threading and other processes.

The TPX series is equipped with a high-efficiency chain-plate type chip conveyor, promptly handling turning chips to keep the precision machining process smooth.

The TPX series’ cutting fluid system delivers precise supply, aiding cooling, chip removal, and tool life extension during high-precision turning of various mechanical parts.