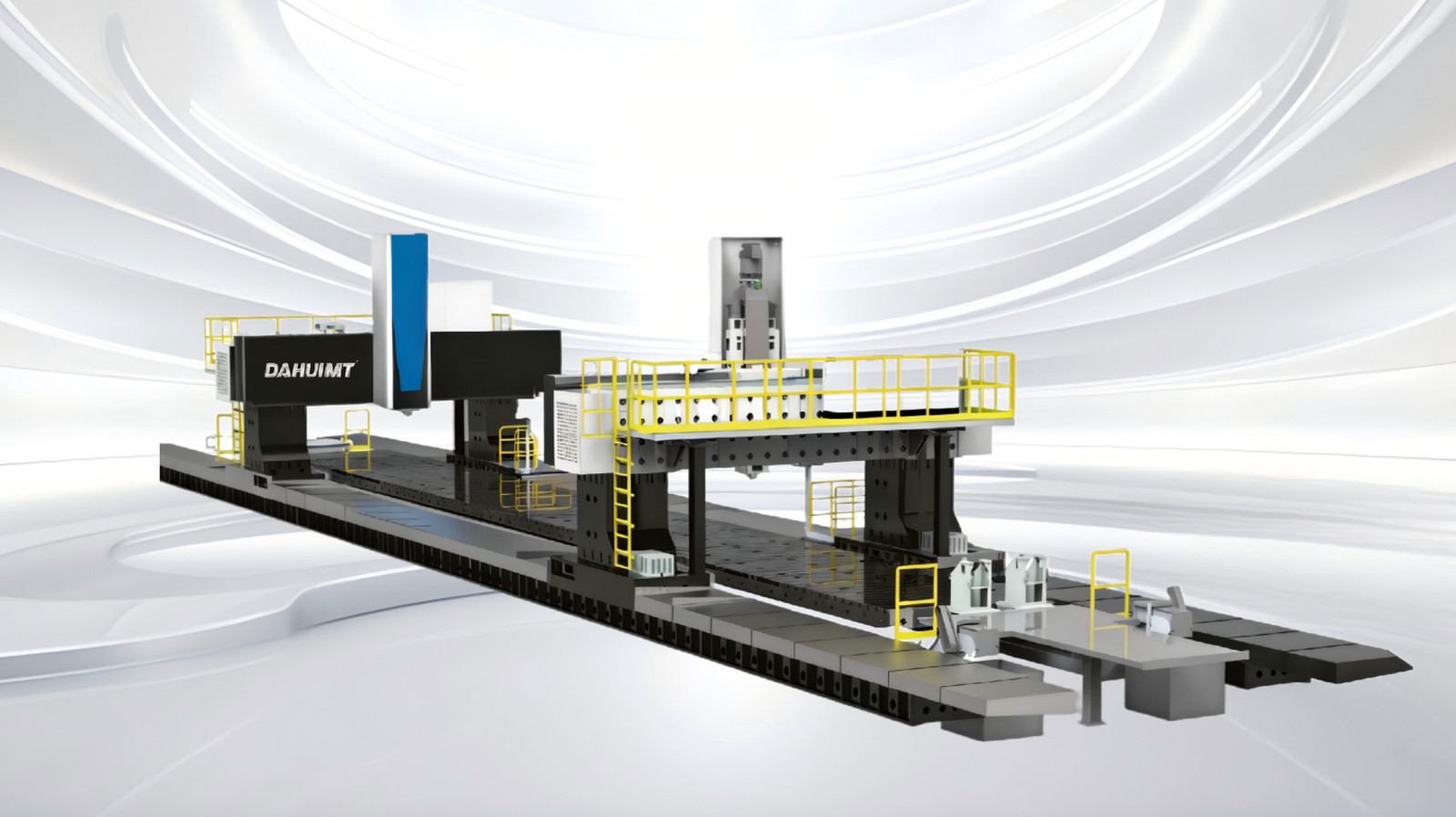

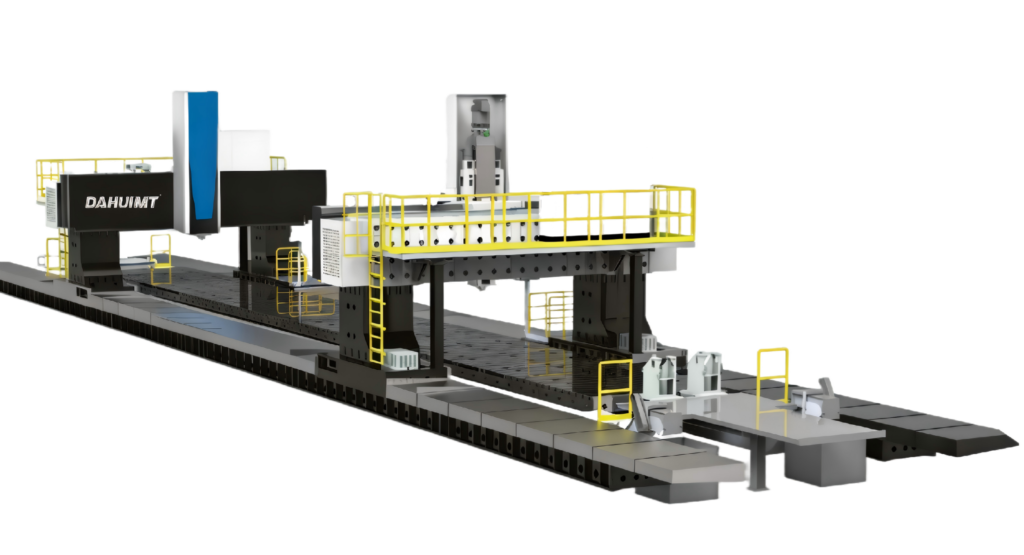

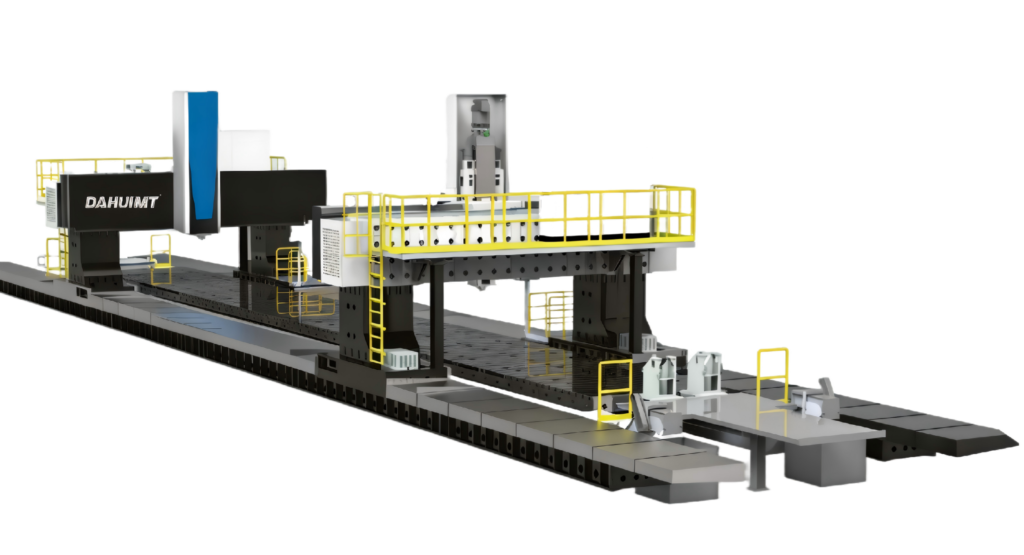

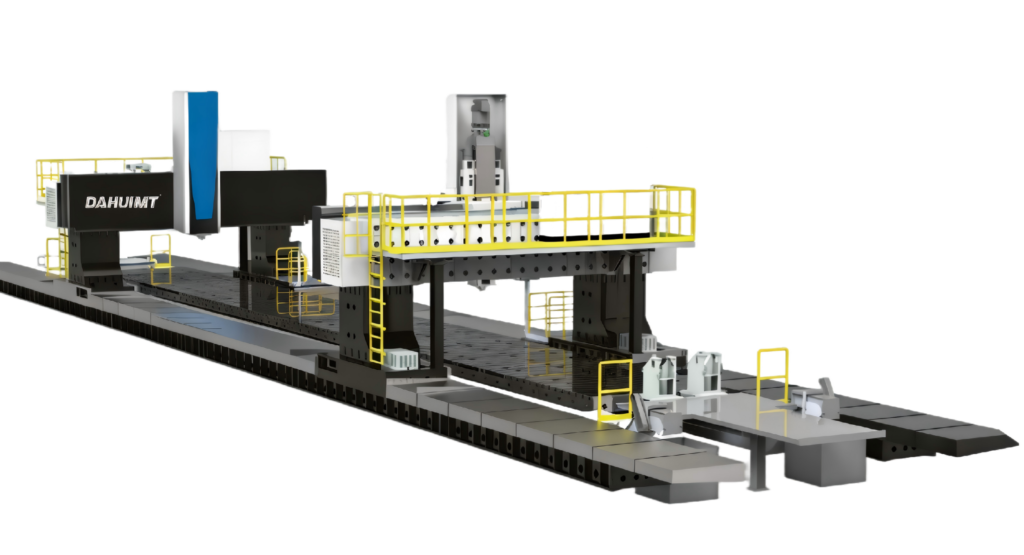

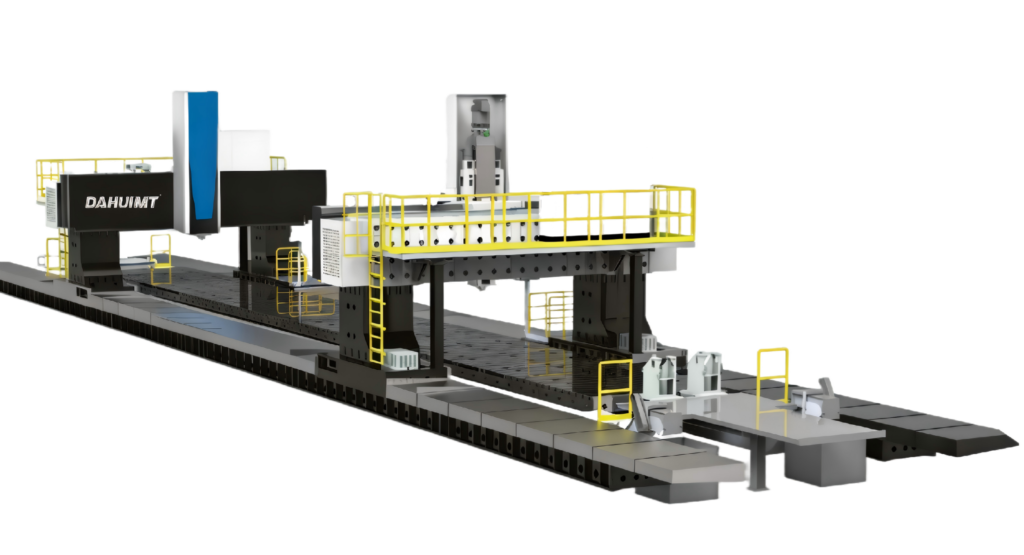

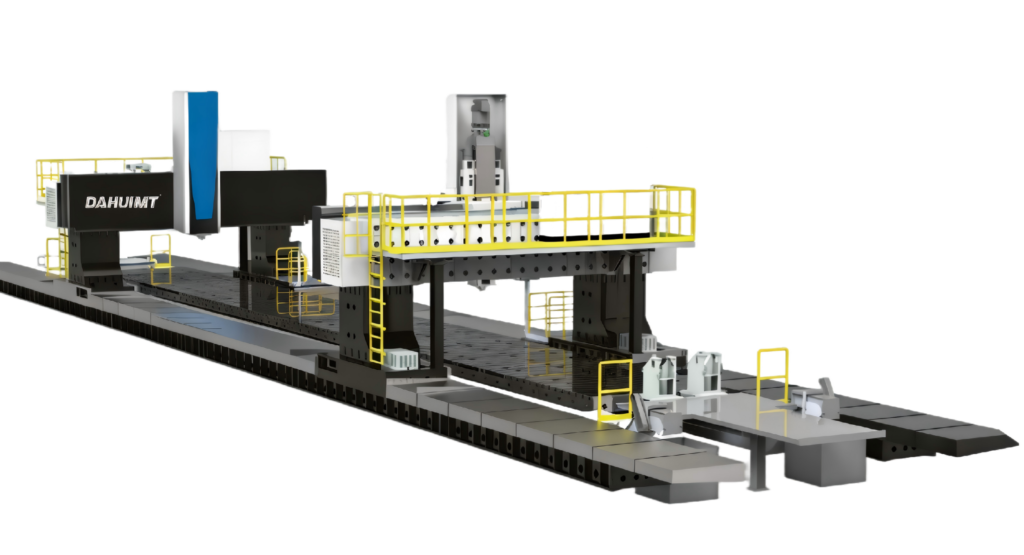

The XKW28 CNC bridge-type moving beam gantry machine enables high-efficiency, precision machining of large heavy parts. With fixed worktable, dual servo-driven moving gantry, four-axis control, 5000×10000mm table, 10,000mm/min feed speed, and 25,000kg load capacity, it ensures stable complex operations.

W-axis stroke:2250/3250/4000mm

Ram form:square ram 500*500/610*610mm

Spindle drive: self-developed gear box/two-speed gear box

Operating system:Siemens/Fanuc

Number of tools:24/32/40/60/80

Processing Expansion:Measuring Device/Tool Setting Instrument/Full Closed Loop Optical

Encoder/AC Axis/Spindle Center Outflow/Accessory Heads

Customized models available

We would be happy to make an individual offer for you!

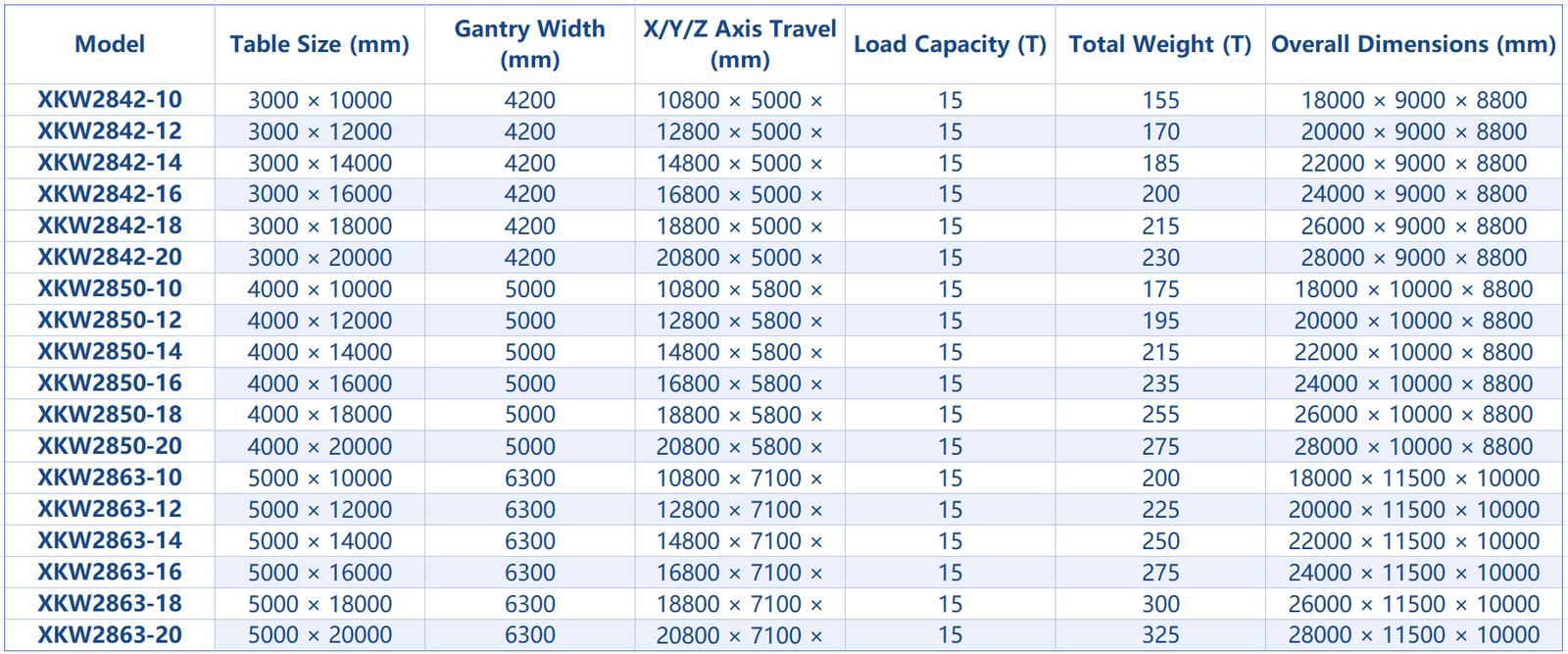

Table Size (mm):3000×10000

Gantry Width (mm):4200

X/Y/Z Axis Travel (mm):10800×5000×1500

Load Capacity (T):15

Total Weight (T):155

Overall Dimensions (mm):18000×9000×8800

Table Size (mm):3000×16000

Gantry Width (mm):4200

X/Y/Z Axis Travel (mm):16800×5000×1500

Load Capacity (T):15

Total Weight (T):200

Overall Dimensions (mm):24000×9000×8800

Table Size (mm):3000×20000

Gantry Width (mm):4200

X/Y/Z Axis Travel (mm):20800×5000×1500

Load Capacity (T):15

Total Weight (T):230

Overall Dimensions (mm):28000×9000×8800

Table Size (mm):4000×10000

Gantry Width (mm):5000

X/Y/Z Axis Travel (mm):10800×5800×1500

Load Capacity (T):15

Total Weight (T):175

Overall Dimensions (mm):18000×10000×8800

Table Size (mm):4000×16000

Gantry Width (mm):5000

X/Y/Z Axis Travel (mm):16800×5800×1500

Load Capacity (T):15

Total Weight (T):235

Overall Dimensions (mm):24000×10000×8800

Table Size (mm):4000×20000

Gantry Width (mm):5000

X/Y/Z Axis Travel (mm):20800×5800×1500

Load Capacity (T):15

Total Weight (T):275

Overall Dimensions (mm):28000×10000×8800

Table Size (mm):5000×10000

Gantry Width (mm):6300

X/Y/Z Axis Travel (mm):10800×7100×2000

Load Capacity (T):15

Total Weight (T):200

Overall Dimensions (mm):18000×11500×10000

Table Size (mm):5000×16000

Gantry Width (mm):6300

X/Y/Z Axis Travel (mm):16800×7100×2000

Load Capacity (T):15

Total Weight (T):275

Overall Dimensions (mm):24000×11500×10000

Table Size (mm):5000×20000

Gantry Width (mm):6300

X/Y/Z Axis Travel (mm):20800×7100×2000

Load Capacity (T):15

Total Weight (T):325

Overall Dimensions (mm):28000×11500×10000

The XKW series adopts topology optimization for gantry (fixed/moving beam) and bed design, integrating WALDRICH-COBURG advanced technology to balance structural rigidity and load-bearing capacity for heavy-duty large-scale machining.

The XKW series is equipped with high-power, high-torque motorized spindles, tailored to match its efficient material removal and heavy-load cutting precision machining requirements.

The XKW series features customized high-response drive solutions (dual AC servo drive for moving beam models), adapting to the efficiency needs of multi-axis linkage and large-stroke machining scenarios.

Relying on rigid gantry structures, precision roller guides and excellent thermal stability, the XKW series maintains consistent stability and IT7-level accuracy in long-term operation.

The XKW series is fitted with an advanced lubrication and cooling system, supporting continuous heavy-duty machining by preventing equipment and spindle thermal deformation.

The XKW series uses mainstream CNC systems (Siemens SINUMERIK ONE/FANUC), ensuring precise operation, strong compatibility and high dynamic performance.

The XKW series covers a wide range of large-scale machining needs, with travels up to 16500mm and worktables up to 5000×20000mm, meeting precision requirements for large structures, boxes and molds.

The XKW series is configured with suitable automatic tool magazine setups, enabling seamless multi-process continuous machining of large heavy parts.

The XKW series is equipped with a high-efficiency chip conveyor, promptly handling heavy cutting chips to keep the large-scale gantry machining process smooth.

The XKW series’ cutting fluid system delivers precise supply, aiding cooling, chip removal, and tool life extension during heavy-duty gantry boring and milling.